-

йӣ»еҢ–еӯё / жқҗж–ҷ / е„ІиғҪиЈқзҪ®жё¬и©Ұ

- и–„иҶңйӣ»еҢ–еӯёж„ҹжё¬еҷЁ

- зңҹз©әйҚҚиҶңзі»зөұ

- жҺҢдёҠеһӢйӣ»еҢ–еӯёе„Җ

- е–®йҖҡйҒ“жҒ’йӣ»дҪҚпјҸжҒ’йӣ»жөҒпјҸдәӨжөҒйҳ»жҠ—еҲҶжһҗе„Җ

- еӨҡйҖҡйҒ“жҒ’йӣ»дҪҚпјҸжҒ’йӣ»жөҒпјҸ дәӨжөҒйҳ»жҠ—еҲҶжһҗе„Җ

- й«ҳеҠҹзҺҮеӨҡйҖҡйҒ“жҒ’йӣ»дҪҚпјҸжҒ’йӣ»жөҒпјҸдәӨжөҒйҳ»жҠ—еҲҶжһҗе„Җ

- йӣ»жұ е……ж”ҫйӣ»еҲҶжһҗе„Җ

- йӣ»еҢ–еӯё/и…җиқ•/иғҪжәҗеҲҶжһҗ

- йӣ»еҢ–еӯёй…Қ件

- жҒҶжә«жҒҶжҝ•/ж°Јж°ӣзҲҗ/и©Ұй©—з®ұ

- зҮғж–ҷйӣ»жұ з ”з©¶

- еҗ«иғҪжқҗж–ҷжё¬и©ҰеҲҶжһҗ

- йӣ»жұ жё¬и©ҰеҲҶжһҗ

- ж¶ІжөҒйӣ»жұ з ”з©¶

- з„Ўз·ҡеҸҜж”ңејҸйӣ»еҢ–еӯё

- йӢ°йӣ»жұ иЈҪзЁӢ

- зҶұеғҸе„ҖеҷЁжҮүз”Ё

- еӨӘйҷҪиғҪе…үдјҸзӣёй—ңиЁӯеӮҷ

- йҺ–зӣёж”ҫеӨ§еҷЁ

-

йӣ»еҠӣиЁӯеӮҷжё¬и©Ұ

- и¶…йҹіжіўжӘўжё¬е„Җ

- йўЁеҠӣзҷјйӣ»ж©ҹз¶ӯиӯ·жё¬и©Ұ

- и®ҠеЈ“еҷЁжё¬и©Ұ

- йӣ»зәңжё¬и©Ұ

- GIS/й–Ӣй—ңжё¬и©Ұ

- йғЁд»Ҫж”ҫйӣ»зӣЈжё¬/иЁәж–·

- зҷјйӣ»ж©ҹ/йҰ¬йҒ”жё¬и©Ұ

- и®Ҡйӣ»жүҖиЁӯеӮҷжё¬и©Ұ

- зө•з·Ј/иҖҗеЈ“/й«ҳеЈ“жәҗ

- дҪҺйӣ»йҳ»йҮҸжё¬е„ҖеҷЁ

- жҺҘең°йӣ»йҳ»йҮҸжё¬е„ҖеҷЁ

- дёҖиҲ¬йӣ»еҠӣжё¬йҮҸе„ҖиЎЁ

- йӣ»еҠӣе“ҒиіӘ/諧波зӣЈжё¬еҲҶжһҗ

- йӣ»еҠӣз¶ӯиӯ·иЁӯеӮҷ

- зҙ«еӨ–з·ҡж”ҫйӣ»еҪұеғҸжӘўжё¬е„Җ

- иіҮж–ҷи’җйӣҶ

- жә«еәҰ/йӣ»йҮҸ/еЈ“еҠӣ/жҢҜеӢ• жё¬йҮҸж ЎжӯЈ

- йӣ»зЈҒжіўе®үе…Ё

- зү©зҗҶеҜҰй©—иЁӯеӮҷ

- еҹәзӨҺз ”з©¶иЁӯеӮҷ

- йқһз ҙеЈһжӘўжё¬иЁӯеӮҷ

-

йӣ»еҢ–еӯё / жқҗж–ҷ / е„ІиғҪиЈқзҪ®жё¬и©Ұ

- и–„иҶңйӣ»еҢ–еӯёж„ҹжё¬еҷЁ

- зңҹз©әйҚҚиҶңзі»зөұ

- жҺҢдёҠеһӢйӣ»еҢ–еӯёе„Җ

- е–®йҖҡйҒ“жҒ’йӣ»дҪҚпјҸжҒ’йӣ»жөҒпјҸдәӨжөҒйҳ»жҠ—еҲҶжһҗе„Җ

- еӨҡйҖҡйҒ“жҒ’йӣ»дҪҚпјҸжҒ’йӣ»жөҒпјҸ дәӨжөҒйҳ»жҠ—еҲҶжһҗе„Җ

- й«ҳеҠҹзҺҮеӨҡйҖҡйҒ“жҒ’йӣ»дҪҚпјҸжҒ’йӣ»жөҒпјҸдәӨжөҒйҳ»жҠ—еҲҶжһҗе„Җ

- йӣ»жұ е……ж”ҫйӣ»еҲҶжһҗе„Җ

- йӣ»еҢ–еӯё/и…җиқ•/иғҪжәҗеҲҶжһҗ

- йӣ»еҢ–еӯёй…Қ件

- жҒҶжә«жҒҶжҝ•/ж°Јж°ӣзҲҗ/и©Ұй©—з®ұ

- зҮғж–ҷйӣ»жұ з ”з©¶

- еҗ«иғҪжқҗж–ҷжё¬и©ҰеҲҶжһҗ

- йӣ»жұ жё¬и©ҰеҲҶжһҗ

- ж¶ІжөҒйӣ»жұ з ”з©¶

- з„Ўз·ҡеҸҜж”ңејҸйӣ»еҢ–еӯё

- йӢ°йӣ»жұ иЈҪзЁӢ

- зҶұеғҸе„ҖеҷЁжҮүз”Ё

- еӨӘйҷҪиғҪе…үдјҸзӣёй—ңиЁӯеӮҷ

- йҺ–зӣёж”ҫеӨ§еҷЁ

-

йӣ»еҠӣиЁӯеӮҷжё¬и©Ұ

- и¶…йҹіжіўжӘўжё¬е„Җ

- йўЁеҠӣзҷјйӣ»ж©ҹз¶ӯиӯ·жё¬и©Ұ

- и®ҠеЈ“еҷЁжё¬и©Ұ

- йӣ»зәңжё¬и©Ұ

- GIS/й–Ӣй—ңжё¬и©Ұ

- йғЁд»Ҫж”ҫйӣ»зӣЈжё¬/иЁәж–·

- зҷјйӣ»ж©ҹ/йҰ¬йҒ”жё¬и©Ұ

- и®Ҡйӣ»жүҖиЁӯеӮҷжё¬и©Ұ

- зө•з·Ј/иҖҗеЈ“/й«ҳеЈ“жәҗ

- дҪҺйӣ»йҳ»йҮҸжё¬е„ҖеҷЁ

- жҺҘең°йӣ»йҳ»йҮҸжё¬е„ҖеҷЁ

- дёҖиҲ¬йӣ»еҠӣжё¬йҮҸе„ҖиЎЁ

- йӣ»еҠӣе“ҒиіӘ/諧波зӣЈжё¬еҲҶжһҗ

- йӣ»еҠӣз¶ӯиӯ·иЁӯеӮҷ

- зҙ«еӨ–з·ҡж”ҫйӣ»еҪұеғҸжӘўжё¬е„Җ

- иіҮж–ҷи’җйӣҶ

- жә«еәҰ/йӣ»йҮҸ/еЈ“еҠӣ/жҢҜеӢ• жё¬йҮҸж ЎжӯЈ

- йӣ»зЈҒжіўе®үе…Ё

- зү©зҗҶеҜҰй©—иЁӯеӮҷ

- еҹәзӨҺз ”з©¶иЁӯеӮҷ

- йқһз ҙеЈһжӘўжё¬иЁӯеӮҷ

жҝәе°„йҚҚиҶңж©ҹе’ҢзҶұи’ёйҚҚе„Җ

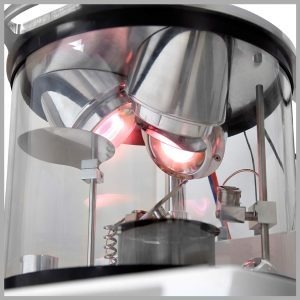

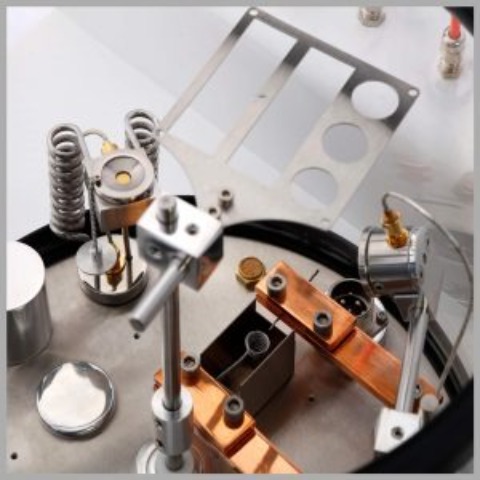

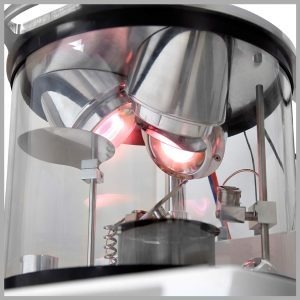

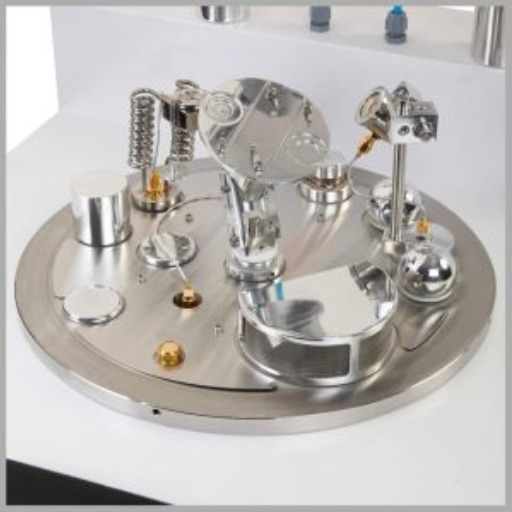

SPUTTER COATER AND THERMAL EVAPORATOR еһӢиҷҹпјҡDST3-TзЈҒжҺ§жҝәе°„йҚҚиҶңж©ҹ DST3-T й…ҚеӮҷдәҶдёҖеҖӢеӨ§и…”й«”пјҲзӣҙеҫ‘ 300 mmпјүе’ҢдёүеҖӢзӣҙеҫ‘2”зҡ„ж°ҙеҶ·йҷ°жҘөпјҢйҒ©еҗҲй•·жҷӮй–“жІүз©ҚгҖӮзЈҒжҺ§жҝәе°„йҚҚиҶңж©ҹй…Қжңүе°„й »е’ҢзӣҙжөҒйӣ»жәҗгҖӮе®ғеҸҜд»Ҙжҝәе°„еҚҠе°Һй«”гҖҒйӣ»д»ӢиіӘе’ҢйҮ‘еұ¬пјҲж°§еҢ–жҖ§е’Ңжғ°жҖ§пјүйқ¶жқҗгҖӮ

жҝәе°„йҚҚиҶңж©ҹзі»зөұй…ҚеӮҷдәҶдёҖеҖӢиҮӘеӢ•иӘҝзҜҖеҢ№й…ҚеҷЁпјҢеҸҜе°Үе°„й »жҝәе°„йҒҺзЁӢдёӯзҡ„еҸҚе°„еҠҹзҺҮйҷҚиҮіжңҖдҪҺгҖӮзӮәдәҶеўһеҠ и–„иҶңиҲҮеҹәеә•зҡ„йҷ„и‘—еҠӣдёҰж”№е–„и–„иҶңзөҗж§ӢпјҢеҸҜеңЁеҹәеә•дёҠж–ҪеҠ 300 V зӣҙжөҒеҒҸзҪ®йӣ»еЈ“пјҲеҸҜйҒёпјү

-

дёүйқ¶жёҰијӘжіөжҝәе°„йҚҚиҶңж©ҹ DST3-T жҳҜдёҖзЁ®еӨҡзңҹз©әйҚҚиҶңж©ҹзі»зөұпјҢе®ғе°ҮзҶұи’ёйҚҚе„Җе’Ңжҝәе°„йҚҚиҶңж©ҹж•ҙеҗҲеңЁдёҖеҖӢз·Ҡж№Ҡзҡ„еҸ°ејҸзі»зөұдёӯгҖӮй«ҳзңҹз©әзі»зөұйҒ©з”Ёж–јеӨҡзЁ®жқҗж–ҷзҡ„жІүз©ҚгҖӮдёүзЈҒжҺ§з®Ўйқ¶еҸ°жҝәе°„йҚҚиҶңж©ҹеҸҜеңЁи’ёйҚҚе’Ңжҝәе°„зӢҖж…ӢпјҲйқһеҗҢжҷӮпјүд№Ӣй–“иј•й¬ҶеҲҮжҸӣгҖӮ

зЈҒжҺ§жҝәе°„йҚҚиҶңж©ҹ DST3-T й…ҚеӮҷдәҶдёҖеҖӢеӨ§и…”й«”пјҲзӣҙеҫ‘ 300 mmпјүе’ҢдёүеҖӢзӣҙеҫ‘2”зҡ„ж°ҙеҶ·йҷ°жҘөпјҢйҒ©еҗҲй•·жҷӮй–“жІүз©ҚгҖӮзЈҒжҺ§жҝәе°„йҚҚиҶңж©ҹй…Қжңүе°„й »е’ҢзӣҙжөҒйӣ»жәҗгҖӮе®ғеҸҜд»Ҙжҝәе°„еҚҠе°Һй«”гҖҒйӣ»д»ӢиіӘе’ҢйҮ‘еұ¬пјҲж°§еҢ–жҖ§е’Ңжғ°жҖ§пјүйқ¶жқҗгҖӮ

жҝәе°„йҚҚиҶңж©ҹзі»зөұй…ҚеӮҷдәҶдёҖеҖӢиҮӘеӢ•иӘҝзҜҖеҢ№й…ҚеҷЁпјҢеҸҜе°Үе°„й »жҝәе°„йҒҺзЁӢдёӯзҡ„еҸҚе°„еҠҹзҺҮйҷҚиҮіжңҖдҪҺгҖӮзӮәдәҶеўһеҠ и–„иҶңиҲҮеҹәеә•зҡ„йҷ„и‘—еҠӣдёҰж”№е–„и–„иҶңзөҗж§ӢпјҢеҸҜеңЁеҹәеә•дёҠж–ҪеҠ 300 V зӣҙжөҒеҒҸзҪ®йӣ»еЈ“пјҲеҸҜйҒёпјү

ж №ж“ҡйҷ°жҘөзҡ„зӢҖж…ӢпјҢDST3-T жңүе…©зЁ®еһӢиҷҹпјҡ

- DST3 – TA (её¶и§’еәҰйҷ°жҘө):

DST3-TA й…ҚеӮҷдәҶдёүеҖӢе…·жңүе…ұеҗҢдёӯеҝғй»һзҡ„и§’еәҰйҷ°жҘөгҖӮжҝәе°„йҚҚиҶңж©ҹзі»зөұеҸҜеҗҢжҷӮжҲ–е–®зҚЁеҫһе…©еҖӢжҲ–дёүеҖӢпјҲеҸҜйҒёпјүйқ¶жқҗдёҠйҖІиЎҢжҝәе°„пјҢд»ҘеҲҶеҲҘеҪўжҲҗеҗҲйҮ‘жҲ–еӨҡеұӨжІүз©ҚгҖӮи©ІжЁЎеһӢдёӯеҹәжқҝзҡ„жңҖеӨ§е°әеҜёеҸҜд»ҘжҳҜ 3 иӢұеҜёгҖӮ

- DST3 -TSпјҲзӣҙејҸйҷ°жҘөпјүпјҡ

DST3-TS й…ҚжңүдёүеҖӢ 2 иӢұеҜёж°ҙеҶ·зӣҙејҸйҷ°жҘөпјҢйҒ©еҗҲжҝәе°„зӣҙеҫ‘йҒ” 20 cmзҡ„е–®дёҖеҖӢеӨ§еһӢжЁЈе“ҒжҲ–еӨҡеҖӢе°ҸеһӢжЁЈе“Ғ

DST3-Tжҝәе°„йҚҚиҶңж©ҹзҡ„зү№й»һ

- з·Ҡж№Ҡзі»зөұдёӯзҡ„жҝәе°„е’ҢзҶұи’ёйҚҚзҡ„е®ҢзҫҺе·Ҙи—қгҖӮ

- й«ҳзңҹз©әзҙҡеҲҘгҖӮ

- й…ҚеӮҷйҒ©з”Ёж–јйҮ‘еұ¬гҖҒеҚҠе°Һй«”е’Ңйӣ»д»ӢиіӘзҡ„зӣҙжөҒе’Ңе°„й »йӣ»жәҗгҖӮ

- её¶дёүеҖӢ2”ж°ҙеҶ·и§’еәҰзЈҒжҺ§йҷ°жҘөпјҢйҒ©з”Ёж–јз”ҹз”ўеҗҲйҮ‘и–„иҶң (DST3-TA) е’ҢеӨҡеұӨжІүз©ҚгҖӮ

- её¶зҶұжәҗиЈқзҪ®гҖӮ

- е…©еҖӢеӣәе®ҡе’ҢеҸҜ移еӢ•зҡ„зҹіиӢұжҷ¶й«”зӣЈжё¬зі»зөұпјҢз”Ёж–јеҚіжҷӮеҺҡеәҰжё¬йҮҸпјҲ1 nmзІҫеәҰпјүгҖӮ

- е…©еҖӢзІҫеҜҶиіӘйҮҸжөҒжҺ§еҲ¶еҷЁпјҢз”Ёж–јиүҜеҘҪжҺ§еҲ¶ж°¬ж°ЈжөҒйҮҸе’ҢеҸҚжҮүжҖ§жҝәе°„ж°Јй«”гҖӮ

- жүӢеӢ•жҲ–иҮӘеӢ•е®ҡжҷӮжҲ–е®ҡеҺҡжІүз©ҚгҖӮ

- жҸҗдҫӣGLAD (Glancing Angle Deposition) жҝәйҚҚжҠҖиЎ“гҖӮ

- зӯүйӣўеӯҗжё…жҙ—гҖӮ

- иҰ–иҰәејҸзҡ„и§ёжҺ§иһўе№•пјҢеҸҜжҺ§еҲ¶жҝәйҚҚйҒҺзЁӢдёҰеҝ«йҖҹијёе…Ҙж•ёж“ҡгҖӮ

- еҸӢе–„зҡ„з”ЁжҲ¶и»ҹй«”д»ӢйқўпјҢдёҰеҸҜйҖҡйҒҺз¶Іи·Ҝжӣҙж–°гҖӮ

- Vac coat з”ўе“ҒеңЁе…ЁзҗғзҜ„еңҚе…§йғҪжңүе…¬е…ұе’Ңз”ўе“ҒиІ¬д»»дҝқйҡӘпјҢд»ҘйҳІ Vac coat зі»зөұйҖ жҲҗд»»дҪ•иІЎз”ўжҗҚеӨұжҲ–дәәиә«еӮ·е®ігҖӮ

- еҸҜзҝ»иҪүе’Ңж”№и®Ҡж—ӢиҪүжЁЈе“Ғжһ¶зҡ„й«ҳеәҰпјҢдёҰеҸҜйҒёж“Үйҷ°жҘөгҖӮ

- 500°CеҹәжқҝеҠ зҶұеҷЁпјҲеҸҜйҒёпјүгҖӮ

- 300 V DC еҹәжқҝеҒҸзҪ®йӣ»еЈ“пјҲеҸҜйҒёпјүгҖӮ

- з„ЎйҷҗжІүз©ҚжҷӮй–“пјҢдёҚжңғз ҙеЈһзңҹз©әгҖӮ

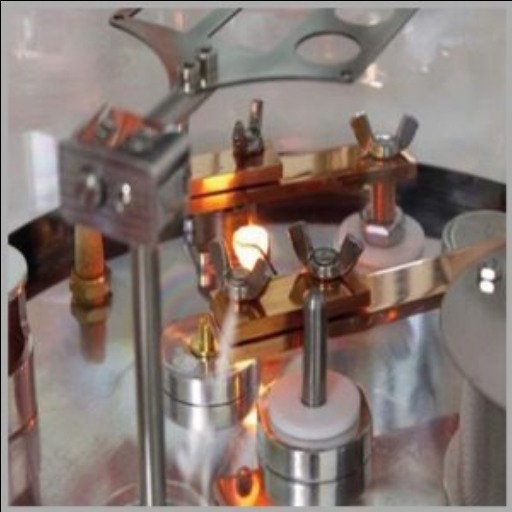

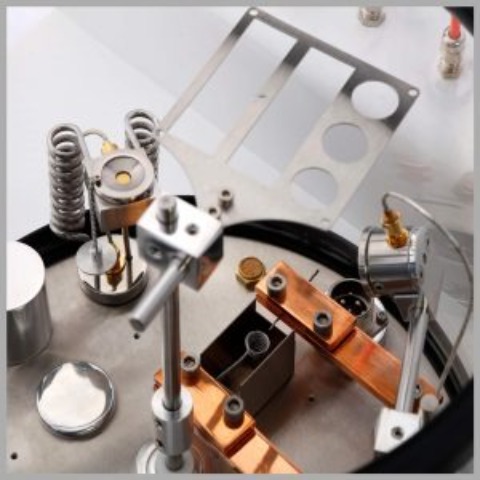

дёүйқ¶жёҰијӘжіөжҝәе°„йҚҚиҶңж©ҹзҡ„зҶұи’ёйҚҚ

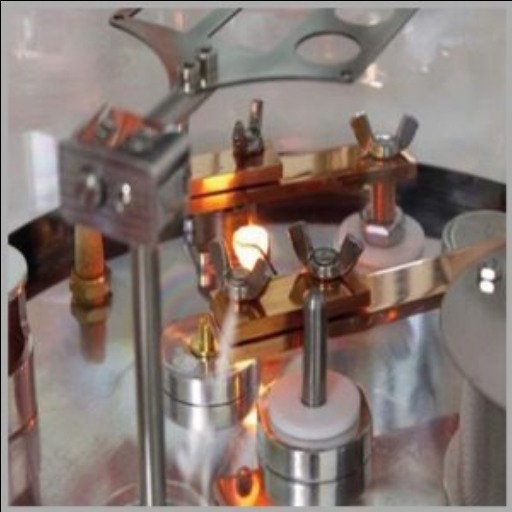

DST3-T й…ҚеӮҷдәҶеӨ§йӣ»жөҒйӣ»жәҗе’ҢдҪҺйӣ»еЈ“пјҲйӣ»йҳ»ејҸпјүзҶұи’ёйҚҚе№іеҸ°пјҢйҒ©еҗҲеҗ„зЁ®зҶұи’ёйҚҚжҮүз”ЁгҖӮжҝәе°„йҚҚиҶңзі»зөұеҸҜе°Үеҗ„зЁ®жқҗж–ҷеҸҜжҺ§ең°зҶұи’ёйҚҚеҲ°еҹәеә•дёҠгҖӮе–®дёҖеҖӢзҶұжәҗж”Ҝжһ¶дёҠеҸҜе®үиЈқдёҚеҗҢйЎһеһӢзҡ„зҶұи’ёйҚҚжәҗпјҲиҲҹеһӢгҖҒзұғеһӢиҲҮз·ҡеңҲеһӢпјүгҖӮ

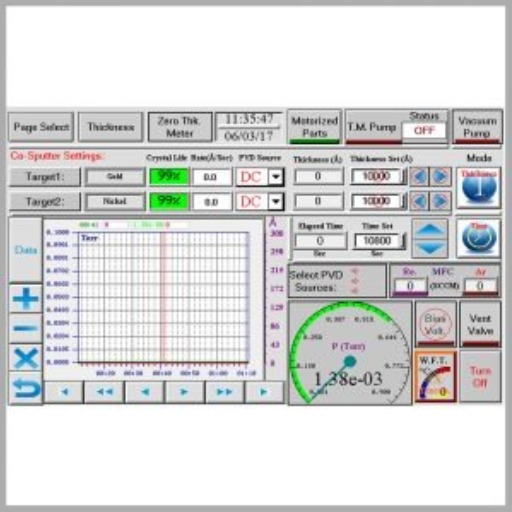

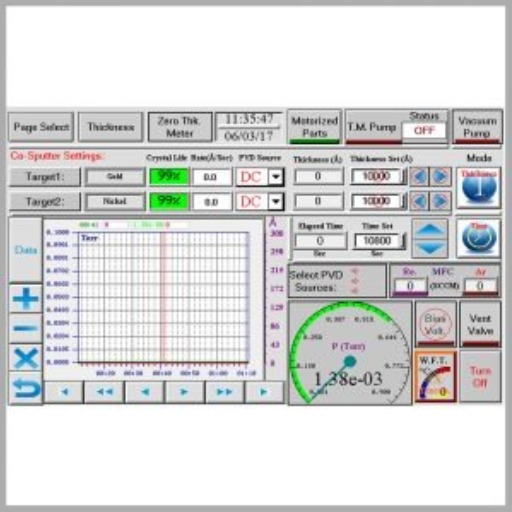

и§ёжҺ§ејҸиһўе№•ж“ҚжҺ§

дёүйқ¶жёҰијӘеҲҶеӯҗжіөжҝәе°„йҚҚиҶңж©ҹй…ҚеӮҷдәҶ 7”еҪ©иүІи§ёжҺ§иһўе№•е’ҢеҚҠиҮӘеӢ•жҺ§еҲ¶еҸҠж•ёж“ҡијёе…ҘиЈқзҪ®пјҢеҚідҪҝжІ’жңү經驗зҡ„з”ЁжҲ¶д№ҹиғҪж“ҚдҪңгҖӮзңҹз©әе’ҢжІҲз©ҚиЁҠжҒҜеҸҜд»ҘеңЁи§ёжҺ§иһўе№•дёҠд»Ҙж•ёеҖјиіҮж–ҷжҲ–жӣІз·ҡзҡ„еҪўејҸйЎҜзӨәгҖӮжңҖеҫҢ 300 ж¬ЎжҝәйҚҚиіҮиЁҠйғҪеҸҜе„ІеӯҳеңЁжӯ·еҸІзҙҖйҢ„й ҒдёҠгҖӮ

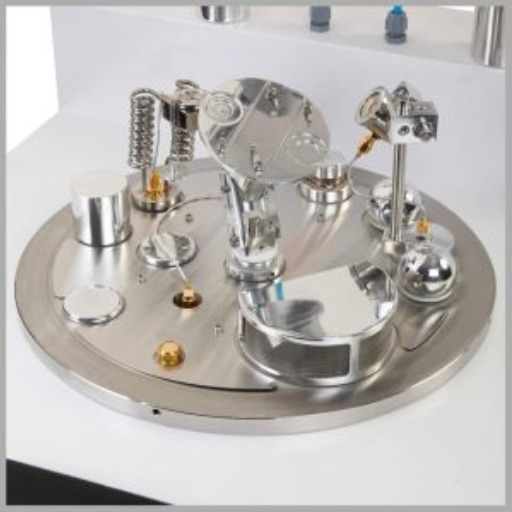

жҝәе°„йҚҚиҶңж©ҹжЁЈе“Ғжһ¶

ж”Ҝжһ¶жҳҜж №ж“ҡйЎҜеҫ®йҸЎијүзҺ»зүҮзҡ„еёёиҰҸе°әеҜёиЈҪдҪңзҡ„пјҢдҪҶдҪҝз”ЁиҖ…еҸҜд»Ҙж №ж“ҡйңҖиҰҒе®ҡиЈҪе°әеҜёгҖӮеңЁжЁЈе“Ғжһ¶дёҠжңүеӨҡеҖӢеӨҫе…·пјҢд»ҘдҫҝеңЁж—ӢиҪүйҒҺзЁӢдёӯдҪҝз”Ёз°Ўе–®зҡ„ж–№жі•еӣәе®ҡе°ҸжЁЈе“ҒгҖӮжҝәе°„йҚҚиҶңж©ҹжҮүз”Ё

- йҮ‘еұ¬гҖҒеҚҠе°Һй«”е’Ңд»ӢиіӘи–„иҶңгҖӮ

- еҘҲзұіе’Ңеҫ®йӣ»еӯҗгҖӮ

- еӨӘйҷҪиғҪйӣ»жұ жҮүз”ЁгҖӮ

- е…ұжҝәйҚҚе·Ҙи—қгҖӮ

- е…үеӯёе…ғ件йҚҚиҶңгҖӮ

- и–„иҶңеӮіж„ҹеҷЁгҖӮ

- зЈҒжҖ§и–„иҶңиЁӯеӮҷгҖӮ

- йӣ»и…ҰиЁҳжҶ¶й«”жҮүз”ЁгҖӮ

- з”Ёж–ј SEM е’Ң FE-SEM жЁЈе“ҒиЈҪеӮҷзҡ„зҙ°йЎҶзІ’зөҗж§ӢжІүз©ҚгҖӮ

- DST3 – TA (её¶и§’еәҰйҷ°жҘө):

-

- High Vacuum Turbomolecular PumpвҖӢ

Pumping Speed 90 l/s 350l/s Ultimate Pressure 7×10-6 Torr 7×10-7 Torr - Two-stage rotary vane pump 4 m3/h

- Independent sputtering control rate for each cathode to produce fine grain structures

- Automatic control of deposition power independent of pressure

- Automatic control of the cathode’s temperatures to protect the life time of the magnets

- Water-cooled high current electric feedthrough

- Two precision Mass Flow Controller (MFC) for fine control of Ar flow and so reactive sputtering gas

- Records and plots of coating parameters graphs

- Transfers curves and deposition process data by a USB port to PC

- 300V DC bias voltage (optional)

- Equipped to plasma cleaner (optional)

- Equipped to 500ЛҡC substrate heater (optional)

- DC power supply 0-1200V, 0-500 mA

- 0-24 V, 0-100 A high current power supply

- 300 W RF power supply with automatic matching box

- Utilities: 220V-240V, 50/60HZ, 16A

- Box Dimensions: 50 cm H x 60 cm W x 47 cm D

- Shipping Weight: 160 kg (Pump, Rack, and Box)

Options and Accessories

The Triple Target Turbomolecular Pumped Sputter Coater – DST3-T has the following options and accessories:

- Quartz crystal sensors

- Spare vacuum glass chamber

- Sputtering Targets

- Thermal source materials

- 300V DC bias voltage

- Plasma cleaner

- 500ЛҡC substrate heater

-

The DST3-T, Triple Target Turbo Pumped Sputter Coater, is a multi vacuum coater system that combines thermal evaporator and sputter coater in one single compact desktop system. The high vacuum system is suitable for deposition of a wide range of materials. Triple magnetron target desk sputter coater can easily switch between Evaporation and Sputtering condition (Not Simultaneously).

The DST3-T, Magnetron Desk Sputter Coater, is equipped with a large chamber (300 mm diameter) and three 2” diameter water-cooled cathodes which make it suitable for long time deposition. The magnetron desk sputter coater is equipped with RF and DC power supplies. It can sputter semiconductors, dielectrics and metal (oxidizing & noble) targets.

The sputter coater system is equipped with an auto adjustable matching box, minimizing the reflected power in the RF sputtering process. For increasing film adhesion to the substrate and to improve the film structures, a 300 V, DC bias voltage can be applied to the substrate (optional).

According to state of the cathodes, DST3-T is available in two models:

- DST3 – TA (Angled Cathodes):

The DST3-TA is equipped with three angled cathodes with a common focal point. The sputter coater system can sputter from two or three (optional) targets simultaneously or independently to form alloys or multilayer deposition respectively. The maximum size of substrates in this model could be 3 inches.

- DST3 –TS (Straight Cathodes):

DST3-TS with three straight 2 inches water-cooled cathodes is suitable for sputtering a single large specimen with diameter up to 20 cm or several small specimens.

Features of DST3-T Sputter Coater

- Sputtering and Thermal Evaporation process in a compact system

- High vacuum level

- Equipped with DC and RF power supplies suitable for metals, semiconductors and dielectrics

- Three 2” water-cooled angled, magnetron cathodes suitable for producing alloy films (DST3-TA) and multilayer deposition

- One thermal source installation

- Two fixed and movable quartz crystal monitoring system for real time thickness measurement (1 nm precision)

- Two MFCs

- Manual or automatic Timed or Thickness deposition

- GLAD Sputtering

- Plasma Cleaning

- Intuitive touch screen to control coating process and rapid data input

- User friendly software that can be updated via network

- Vac coat Products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

- Tillable and change height of rotary sample holder with ability to selection of the cathodes

- 500 °C substrate heater (optional)

- 300 V DC substrate bias voltages (optional)

- Unlimited deposition time without breaking vacuum

Thermal Evaporation of Triple Target Turbo Pumped Sputter Coater

The DST3-T is equipped with a high current power supply and low-voltage (resistive) thermal evaporation platform suitable for a wide variety of thermal evaporation applications. The sputter coating system allows controlled thermal evaporation of wide range materials onto substrate. Different types of thermal evaporation sources (Boat, Basket, and Coil) can be installed on the single thermal source holder.

Touch Screen Control

Triple Target Turbomolecular Pumped Sputter Coater is equipped with a 7” colored touch screen and semi-automatic control and data input that can be operated by even inexperienced users. The vacuum and deposition information can be observed as digital data or curves on the touch screen. Information of the last 300 coating can also be saved in the history page.

Sputter Coater Sample Holder

The holder is made according to the conventional size of microscope slides, but the user can order customize size according to his/her needs. On the sample holder number of clamps are created to hold the small samples with a simple method during the rotation.

Sputter Coater Applications

- Metal, Semiconductor, and Dielectric Films

- Nano & Microelectronic

- Solar cell applications

- Co-Sputtering processes

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

- Computer memory applications

- Fine grain structural deposition for SEM & FE-SEM sample preparation

- DST3 – TA (Angled Cathodes):

-

- High Vacuum Turbomolecular PumpвҖӢ

Pumping Speed 90 l/s 350l/s Ultimate Pressure 7×10-6 Torr 7×10-7 Torr - Two-stage rotary vane pump 4 m3/h

- Independent sputtering control rate for each cathode to produce fine grain structures

- Automatic control of deposition power independent of pressure

- Automatic control of the cathode’s temperatures to protect the life time of the magnets

- Water-cooled high current electric feedthrough

- Two precision Mass Flow Controller (MFC) for fine control of Ar flow and so reactive sputtering gas

- Records and plots of coating parameters graphs

- Transfers curves and deposition process data by a USB port to PC

- 300V DC bias voltage (optional)

- Equipped to plasma cleaner (optional)

- Equipped to 500ЛҡC substrate heater (optional)

- DC power supply 0-1200V, 0-500 mA

- 0-24 V, 0-100 A high current power supply

- 300 W RF power supply with automatic matching box

- Utilities: 220V-240V, 50/60HZ, 16A

- Box Dimensions: 50 cm H x 60 cm W x 47 cm D

- Shipping Weight: 160 kg (Pump, Rack, and Box)

Options and Accessories

The Triple Target Turbomolecular Pumped Sputter Coater – DST3-T has the following options and accessories:

- Quartz crystal sensors

- Spare vacuum glass chamber

- Sputtering Targets

- Thermal source materials

- 300V DC bias voltage

- Plasma cleaner

- 500ЛҡC substrate heater