桌上型熱蒸鍍儀

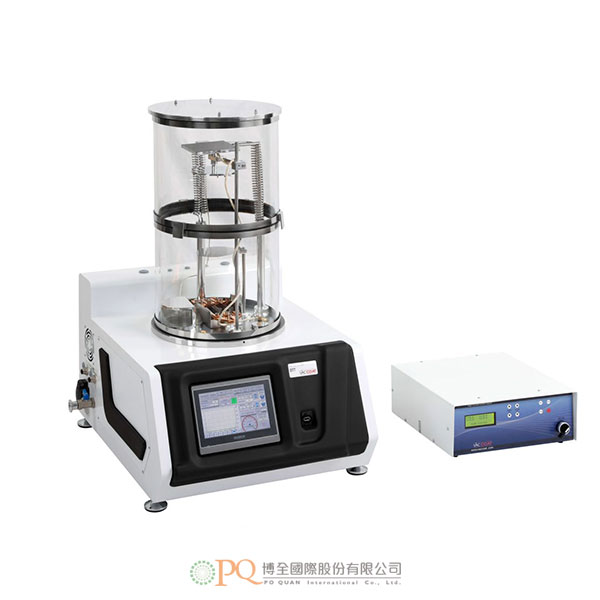

DESK THERMAL EVAPORATOR 型號:DTTDTT 是用於薄膜真空沉積的台式渦輪分子泵熱蒸鍍儀。帶蒸發源(舟型/籃型/線圈)選擇系統的三源蒸鍍儀或台式熱蒸發儀是沉積多層膜或合金的理想選擇。

-

DTT 是用於薄膜真空沉積的台式渦輪分子泵熱蒸鍍儀。帶蒸發源(舟型/籃型/線圈)選擇系統的三源蒸鍍儀或台式熱蒸發儀是沉積多層膜或合金的理想選擇。

這種真空蒸鍍儀具有合適的尺寸,能夠在短時間內達到所需的壓力,鍍膜過程可在幾分鐘內完成。它適用於研究、實驗室和電子顯微鏡應用

特點 泵壓速率 90 l/s 350 l/s 極限壓力 7 x10-6 Torr 7 x10-7 Torr - 多層熱塗佈

- 等離子清洗

- 大型腔體

- 高真空渦輪分子泵

- 雙級旋轉葉片前級泵,4m3/h。

- 全量程真空計。

- 為多層薄膜沉積選擇蒸鍍源(舟型/籃型/線圈型)。

- 共蒸鍍形成合金薄膜(可選)。

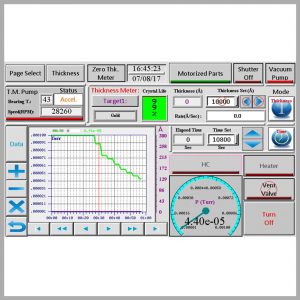

- 石英晶體監測系統,用於即時厚度測量(精度 1 nm)。

- 手動或自動定時或定厚沉積。

- 視覺式的觸控螢幕可控制塗佈過程,並快速輸入數據。

- 友善的用戶軟體介面,並可通過網路更新。

- 配備電子快門。

- 配備旋轉樣品支架(選配)。

- 2 英寸 500 °C 基底加熱器(選配)。

- Vac coat 產品在全球範圍內都有公共和產品責任保險,

以防 Vac coat 系統造成任何財產損失或人身傷害。

應用 - 金屬和介質薄膜

- 製造薄膜感測器

- 光學元件

- 奈米與微電子

- 太陽能電池

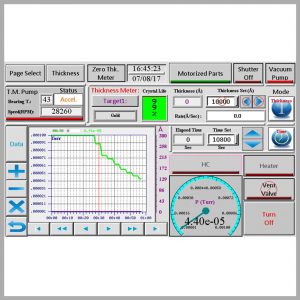

觸控式螢幕操控

台式熱蒸鍍儀配備了 7”彩色觸控螢幕,具有全自動控制和數據輸入功能,即使沒有經驗的用戶也能操作。真空和沈積訊息可通過觸控螢幕上以數值資料或曲線的形式顯示。最後 300 次濺鍍資訊都可儲存在歷史紀錄頁上。

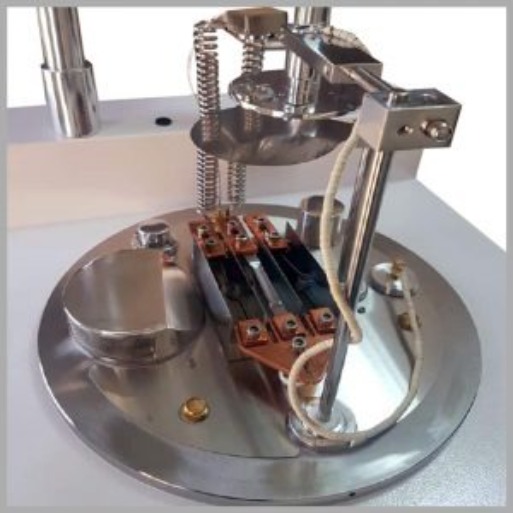

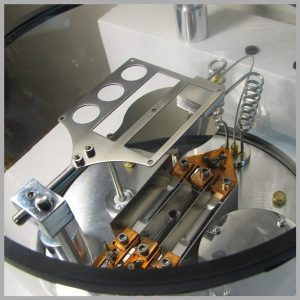

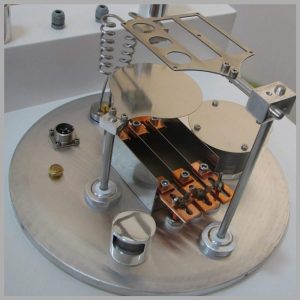

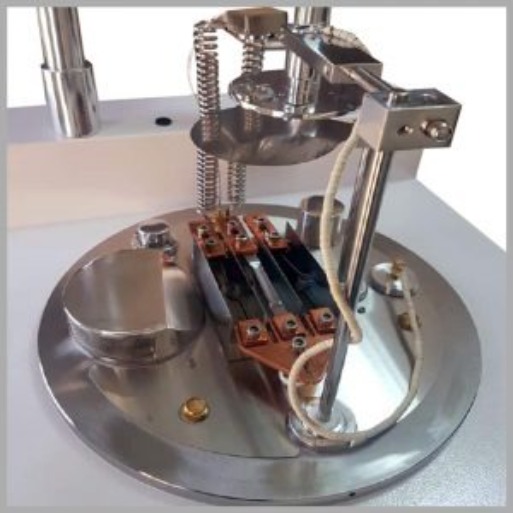

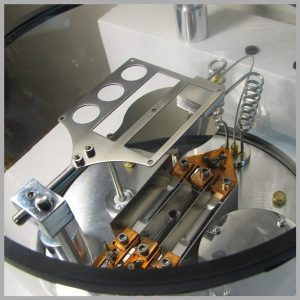

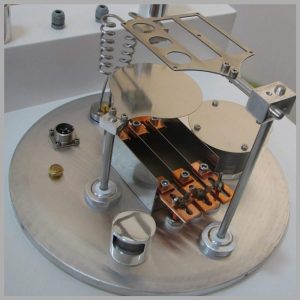

熱蒸鍍源(舟型/籃型/線圈)

台式熱蒸鍍儀可安裝三個獨立的熱電阻熱蒸鍍源。蒸鍍源支架的良好設計不會造成來源材料之間的相互污染。蒸鍍源支架的長度可在 5 cm至 9 cm的範圍內調節。

-

- Multi boats, baskets and coils installation

- Records and plots coating parameters graphs

- Transfers the curves and deposition process data by USB port to PC

- High current electrical feedthrough

- 0-100 high current, protected against short circuit, DC power supply

- Utilities: 220V-240V, 50/60 HZ, 16A

- Dimensions: 60 Cm H × 65 Cm W × 50 Cm D

- Shipping weight: ~ 60 kg

The DTT has the following options and accessories:- High current power supply for co-evaporation

- Quartz crystal sensors

- Spare glass chamber

- Evaporation sources (boat/basket/coil)

- 2 inches, 500 °C substrate heater

- Sample rotation

- MFC

- Sealing gaskets

-

The DTT is a desktop turbomolecular pumped thermal evaporator for vacuum deposition of thin films. The triple-source evaporation or desk thermal evaporator with evaporation source (boat/basket/coil) selection system is ideal for deposition of multilayers or alloys.

This vacuum evaporator with its suitable dimensions is capable of reaching the desired pressure in a short time and coating process can take place within a few minutes. It is suitable for research, laboratory and electron microscopy applications.

Features - Multi-layer thermal coatings

- Plasma Cleaning

- Large format chamber

- High vacuum turbomolecular pump

Pumping Speed 90 l/s 350 l/s Ultimate Pressure 7 x10-6 Torr 7 x10-7 Torr

- Two stage rotary vane backing pump, 4m3/h

- Full range vacuum gauge

- Evaporation source (boat/basket/coil) selection for multilayer thin film deposition

- Co–evaporation to form alloy films (optional)

- Quartz crystal monitoring system for real time thickness measurement (1 nm precision)

- Manual or automatic Timed or Thickness deposition

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software that can be updated via network

- Equipped with electronic shutter

- Equipped with rotary sample holder (optional)

- 2 inches, 500 °C substrate heater (optional)

- Vac coat Products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

Applications

- Metal & dielectric Films

- Fabrication of thin film sensors

- Optical components

- Nano & Microelectronic

- Solar Cells

Touch screen control with colorful display

The desk thermal evaporator is equipped with a 7” colored touch screen with full automatic control and data input that can be operated by even inexperienced users. The vacuum and deposition information can be observed as digital data or curves on the touchscreen. Information of the last 300 coatings can also be saved in the history page.

Thermal Evaporation Sources (boat/basket/coil)

The desk thermal evaporator can be fitted with three independent heat resistance thermal evaporation sources. The good design of the evaporation source holder causes no contamination from source materials on each other. The length of the source holders can be adjusted in the range of 5cm~9cm.

-

- Multi boats, baskets and coils installation

- Records and plots coating parameters graphs

- Transfers the curves and deposition process data by USB port to PC

- High current electrical feedthrough

- 0-100 high current, protected against short circuit, DC power supply

- Utilities: 220V-240V, 50/60 HZ, 16A

- Dimensions: 60 Cm H × 65 Cm W × 50 Cm D

- Shipping weight: ~ 60 kg

The DTT has the following options and accessories:- High current power supply for co-evaporation

- Quartz crystal sensors

- Spare glass chamber

- Evaporation sources (boat/basket/coil)

- 2 inches, 500 °C substrate heater

- Sample rotation

- MFC

- Sealing gaskets