OKOSCAN UT 73 HS,適用於福特 F350 XL (SUPER DUTY)

OKOSCAN UT 73 HS for Ford F350 XL (SUPER DUTY) 型號:OKOSCAN UT 73 HS Pickup-

OKOSCAN UT 73HS 是一套可安裝在路面車輛上(圖為福特 F350 XL(SUPER DUTY))的高速超聲波鋼軌檢測系統,測試速度可高達40公里/小時 (24.85英里/小時)。

本系統包含:

- 超聲波平台車,在檢測模式下它在路面車輛後面同步移動並監測軌距變化。平台車收放由氣動系統控制。

- 安裝在車身上的設備(UT頻道、自動控制箱、液壓站、空氣壓縮機、耦合液容器、供水系統、平台車液壓升降系統)。操作員工作區位於車廂的後排並備有監控系統。

UDS2-73 (下沉式車輪)

平台車配備:- 每側2個,共4個車輪下沉單元 (RSUI)

- 1個4MHz 0° 探頭

- 3個2MHz 70° 探頭

- 1個2MHz 50° 側視探頭

- 1個2MHz 37° 探頭

- 備有步進馬達的RSUI定位系統 (由操作員控制升降、橫移、傾斜)

- 氣動平台車收放系統,用以監控軌距輔助RSUI從軌道中軸定位

- 追蹤路徑座標的編碼器

- 探頭視像監控系統

- RSUI供水系統 (手動調節水龍頭、水管、噴嘴)

車身包含:

- 至少24個超聲波模組OKO-24,頻率範圍為1至7 MHz,探測脈衝頻率高達4 kHz

- 自動控制箱

- 液壓平台車升降系統

- 平台車收放系統的空氣壓縮機

- RSUI供水系統

- 平台車可進行連續超聲波檢測(UT)包含整條鋼軌和橫截面,但不包含軌腳邊緣,速度可高達40公里/小時 (24.85 英里/小時)

- 預設檢測軌距為1435 – 1676毫米 (可跟據企業需求客製化)

- 本系統可以檢測所有AREMA列明類型的瑕疵:橫向和縱向裂紋、螺栓孔裂紋等

- 本系統測量瑕疵參數並將檢測結果保存到資料庫中,以便後續查看和分析

- 本系統超聲波檢測採用脈衝回波和回波影像技術

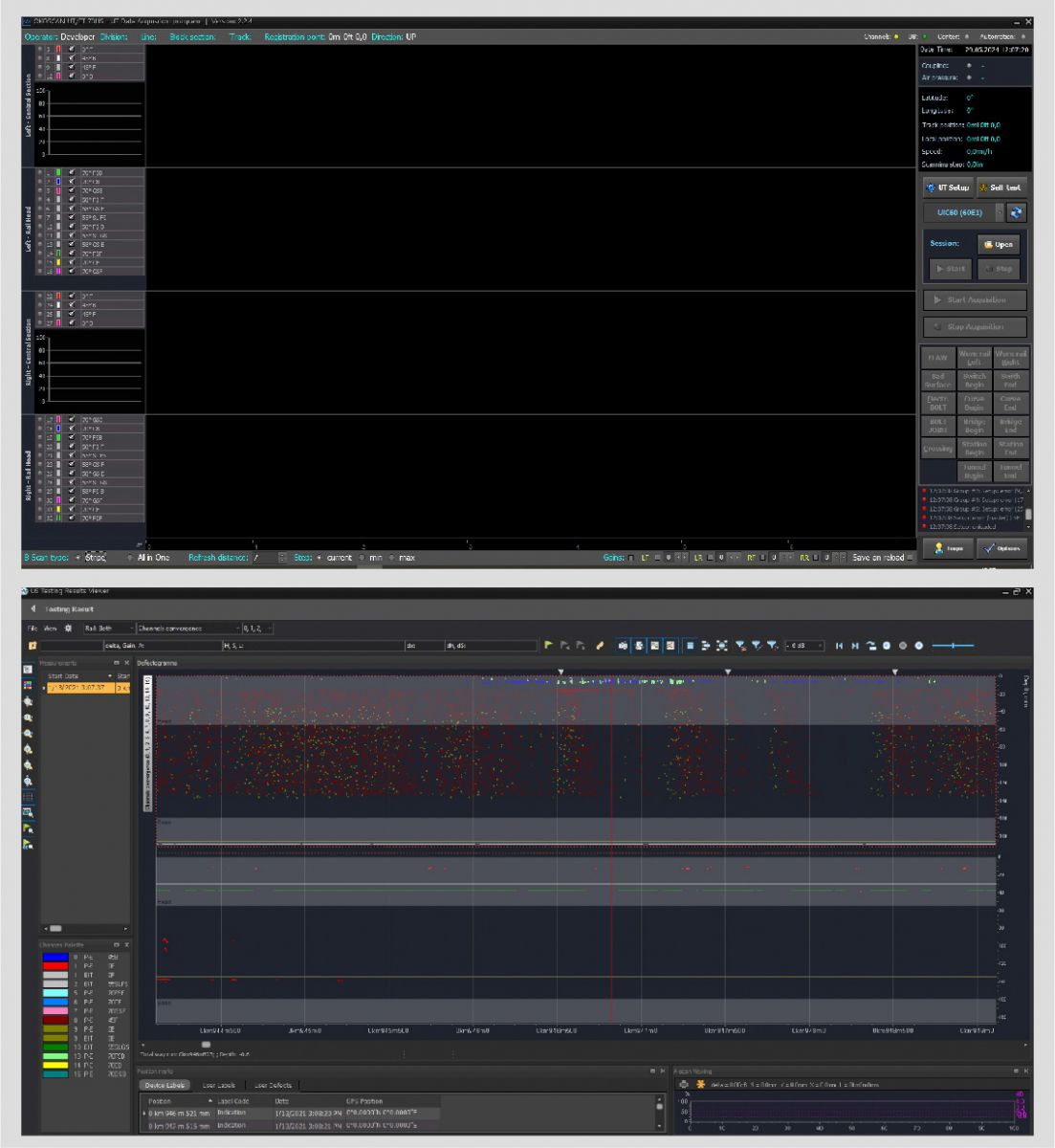

OKOSCAN UT 73 HS 的硬體和運算系統:

- 處理和視像化檢查結果的設備位於操作員工作區內

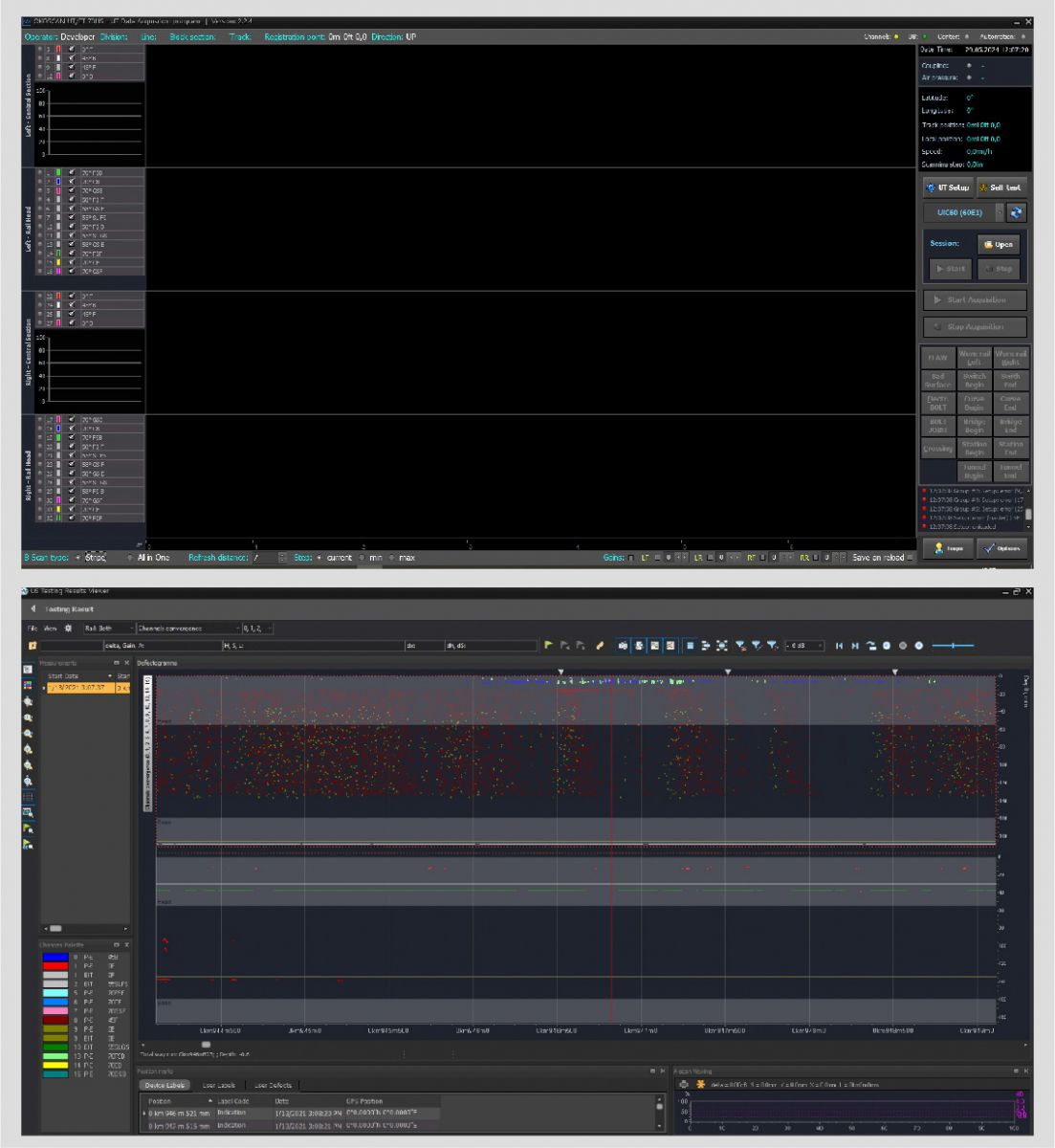

- 本設備可以收集檢測結果數據,以各種模式(A-scan、B-scan)進行視像化並生成檢測報告,通過3G/4G網路傳輸檢測結果

預裝軟體備有以下功能: - 自動瑕疵識別及分類

- UT控制頻道設定 (增益、掃描參數、RFC、探頭參數、閘門參數),並將設定保存在記憶體中

- 在A-scan和B-scan模式下,所有頻道的檢測結果會即時視像化

- 起始座標、檢查區域數據、和軌跡數據登記

- 查看檢查結果數據,並附有標準資料庫管理系統功能 (根據設定的參數進行排序和採樣)

- 生成檢測報告 (也採用Excel格式)

- HDD記憶體容量為您保存至少10,000公里測試的檢測結果

- 將檢測到的瑕疵自動連結到路徑和GPS座標

-

OKOSCAN UT 73HS is a high-speed ultrasonic testing system for rails with testing speed of up to 40 km/h (24.85 mph) which is installed onto the customer`s vehicle (based on Ford F350 XL (SUPER DUTY) with combined course car.

The System consists of:

a) an ultrasonic trolley which simultaneously moves behind the vehicle in testing mode and monitors the changes in the track gauge (track width) through the pneumatic system for trolley decompression

b) equipment installed in the vehicle body (UT channels, automation and control box, hydraulic station, air compressor, container for coupling liquid, water supply system, hydraulic system for lifting and lowering the trolley). The operator's workplace with control monitors is located at the rear seat in the vehicle cabin.

UDS2-73 (Immersion wheel)

The trolley is equipped with:

- 4 roller immersion search unit (RSUI) (2 pcs on each side of the trolley)

Each unit includes:

- 0° probe, 4 MHz – 1 pc

- 70° probe, 2 MHz – 3 pcs

- 50° probe (side looking), 2 MHz – 1 pc

- 37° probe, 2 MHz – 1 pc

- Positioning system for RSUI using stepper motor drives (lifting/lowering, transverse displacement, tilt; operator-guided).

- A pneumatic trolley decompression system allows to monitor the track gauge and thereby position RSUI along the rail axis.

- Encoder for tracking the path coordinates.

- Video surveillance system of probe units.

- Water supply system for RSUI (manual adjustment taps, tubes, nozzles)

The vehicle body includes:

- Ultrasonic modules OKO-24 (at least 24 pcs) with frequency range from 1 to 7 MHz and sounding pulses frequency of up to 4 kHz.

- Automation and control boxes

- Trolley lifting and lowering system with hydraulic station

- Air compressor for trolley decompression system

- Water supply system under RSUI

OKOSCAN UT 73 HS features:

- The trolley performs continuous ultrasonic testing (UT) of double-rail track along the whole length and cross-section, except for rail foot flanges at a speed of up to 40km/h (24.85 mph)

- The gauge of the track under testing is 1435 – 1676 mm (can be changed at the Buyer`s request)

- The system allows detecting all types of defects: transverse and longitudinal horizontal cracks, cracks from bolt holes, etc. according to AREMA listing.

- The system measures defect parameters and saves inspection results to the database with the possibility of subsequent viewing and analysis.

- The System implements the following ultrasonic testing methods: pulse-echo and echo-shadow techniques.

OKOSCAN UT 73 HS’s hardware and computing system:

- Equipment for processing and inspection results visualization is located at the operator’s workplace in the vehicle cabin.

- The equipment provides for collection of inspection results data, visualization in various modes (A-scan, B-scan), generation of inspection reports, and the possibility of inspection results transmition through mobile operators via the 3G/4G protocol.

Pre-installed Software ensures the following functions: - Automatic defect identification and their classification.

- UT control channels settings (gain, sweep parameters, RFC, probe parameters, gates parameters) and saving settings in storage.

- Inspection results visualization simultaneously in B-scan and A-scan modes for all channels in real time.

- Starting coordinate registration, inspection area data registration, track data registration.

- Viewing inspection results data with the possibility to implement all standard DBMS functions (sorting and sampling according to agreed parameters).

- Formation of inspection protocols (also in Excel format).

- Memory capacity (HDD) allows you to save inspection results of at least 10,000 km of testing

- Automatic linking of the detected defect to path and GPS coordinates.