-

micrux

micrux

-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

AWSensors

AWSensors

-

Automatic Research

Automatic Research

-

BASI

BASI

-

BRS

BRS

-

BWB Technologies

BWB Technologies

-

Cmc

Cmc

-

CTRL

CTRL

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Coxem

Coxem

-

C-Tech

C-Tech

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

ECH

ECH

-

Elsys

Elsys

-

Enervac

Enervac

-

Enapter

Enapter

-

ELVEFLOW

ELVEFLOW

-

EA Technology

EA Technology

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Electrothermal

Electrothermal

-

FASTEC

FASTEC

-

GE

GE

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HTW

HTW

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

Labnics

Labnics

-

Ida

Ida

-

LIQUID

LIQUID

-

Instytut Fotonowy

Instytut Fotonowy

-

KEHUA TECH

KEHUA TECH

-

JGG

JGG

-

HVPD

HVPD

-

Jenway

Jenway

-

Jacomex

Jacomex

-

IVIUM

IVIUM

-

ndb

ndb

-

OZM

OZM

-

Redoxme

Redoxme

-

Serstech

Serstech

-

SATIR

SATIR

-

VacCoat

VacCoat

-

Zurich

Zurich

- micrux

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- AWSensors

- Automatic Research

- BASI

- BRS

- BWB Technologies

- Cmc

- CTRL

- CALMET

- CHECKLINE

- Coxem

- C-Tech

- DV Power

- DANATRONICS

- ECH

- Elsys

- Enervac

- Enapter

- ELVEFLOW

- EA Technology

- EL-CELL

- ENERGY SUPPORT

- Electrothermal

- FASTEC

- GE

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GREENLIGHT

- GRZ

- HTW

- HIGH SENSE SOLUTIONSHTW

- HUBER

- Labnics

- Ida

- LIQUID

- Instytut Fotonowy

- KEHUA TECH

- JGG

- HVPD

- Jenway

- Jacomex

- IVIUM

- ndb

- OZM

- Redoxme

- Serstech

- SATIR

- VacCoat

- Zurich

桌上型濺射鍍膜機

DESK SPUTTER COATER 型號:DSR1生產出的薄膜適用於掃描電子顯微鏡 (SEM) 分析。台式磁控濺射鍍膜機是一種高生產率工具,可在全自動系統中提供一致且重複性高的結果。 SEM 鍍膜系統的設計符合人體工程學,體積小是其特點並使用上極為方便。

-

濺射鍍膜機- DSR1 是一種架構緊湊的鍍膜系統,可在不導電或導電性差的樣品上鍍金(Au)、鈀(Pd)、鉑(Pt) 和金/鈀(Au/Pd) 等貴金屬薄膜。可在快速循環時間內形成細粒度均勻的薄膜。

生產出的薄膜適用於掃描電子顯微鏡 (SEM) 分析。台式磁控濺射鍍膜機是一種高生產率工具,可在全自動系統中提供一致且重複性高的結果。 SEM 鍍膜系統的設計符合人體工程學,體積小是其特點並使用上極為方便。

特點

- 雙級直接驅動 4m3/h 旋轉葉片泵。

- 高精度石英晶體厚度監測儀。

- 視覺式的觸控螢幕,可控制濺鍍過程並快速輸入數據。

- 友善的用戶軟體介面,並可通過網路更新。

- 控制塗佈率,獲得更精細的顆粒結構。

- 手動或自動定時濺射和厚度濺射。

- 提供GLAD (Glancing Angle Deposition) 濺鍍技術。

- 等離子清洗。

- 易於更換的樣品(標準配置為行星旋轉或旋轉平台)。

- 符合 CE 標準。

- Vac coat 產品在全球範圍內都有公共和產品責任保險,以防 Vac coat 系統造成任何財產損失或人身傷害。

應用

該系統是一個掃描電子顯微鏡樣品製備系統,配備了一個旋轉泵,可實現低於 50 mTorr 的真空度,這是貴金屬濺射鍍膜的合適真空範圍。

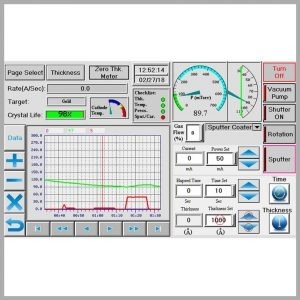

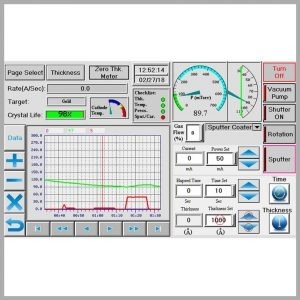

帶彩色顯示器的觸控螢幕操控

該台式濺射鍍膜機配備了 7” 彩色觸控螢幕、全自動控制和數據輸入,即使沒有經驗的用戶也能操作。真空、電流和沉積訊息亦可在觸控螢幕上以數值資料或曲線的形式顯示。最後 300 次濺鍍資訊都可儲存在歷史紀錄頁上。

樣品支架

DSR1 可根據用戶要求配備不同的樣品台配置。標準樣品台可旋轉,高度、角度可調,更換方便。

旋轉式行星樣品台是對多孔樣品進行均勻塗佈的理想選擇。

-

Specifications

- 170 mm OD x 140 mm pyrex cylinder chamber

- Dimensions: 47 Cm H x 46 Cm W x 37 Cm D

- Shipping Weight (included vacuum pump): 42Kg

- Utilities: 220V-240V, 50/60HZ, 10A

- 80 Watt DC switching power supply

- High precision thickness monitor

- Ultimate Vacuum: Less than 40 mTorr

- 2 inches magnetron cathode

- Electronic shutter

- Electronic leak valve

- Transfer the curves and sputtering process data by USB port to PC

- Quartz crystal sensors

- Planetary Sample Rotation

- Spare glass chamber

- Sputtering targets

- Sealing gaskets

-

Sputter Coater – DSR1 is a compact coating system able to coat noble metals such as gold (Au), palladium (Pd), platinum (Pt) and gold/palladium (Au/Pd) thin films on non-conductive or poorly conductive specimens. Uniform thin films with fine-grain sizes are formed in a fast cycle time. The produced thin film is suitable for scanning electron microscopy (SEM) analysis. The Desk Magnetron Coater is a high productivity tool that delivers consistent and highly repeatable results in the fully automated system. The ergonomic design and small footprint of the SEM coating system allows easy use of the system.

Features

- Two-stage, direct drive 4m3/h, rotary vane pump

- High precision quartz crystal thickness monitor

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software that can be updated via network

- Control coating rate to achieve finer grain structures

- Manual or automatic Timed and Thickness sputtering

- GLAD Sputtering

- Plasma Cleaning

- Easy-to-change specimen stages (Planetary rotation or rotation stage as standard)

- Two-year warranty

- CE conformity

- Vac coat Products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

Applications

The system is a scanning electron microscope sample preparation system that equipped with a rotary pump to achieve vacuum less than 50 mTorr which is a suitable vacuum range for noble metals sputter coating

Touch Screen Control with Colorful Display

The desk sputter coater is equipped with a 7” colored touch screen and full automatic control and data input that can be operated by even inexperienced users. The vacuum, current and deposition information can be observed as digital data or curves on the touch screen. Information of the last 300 coating can also be saved in the history page.

Sample Holder

The DSR1 can be equipped with different sample stage configurations depending on the user requirements. The standard sample stage is rotatable with adjustable height, angel and can be changed easily.

The rotary planetary sample stage is a good choice for uniform coating of porous specimens

-

Specifications

- 170 mm OD x 140 mm pyrex cylinder chamber

- Dimensions: 47 Cm H x 46 Cm W x 37 Cm D

- Shipping Weight (included vacuum pump): 42Kg

- Utilities: 220V-240V, 50/60HZ, 10A

- 80 Watt DC switching power supply

- High precision thickness monitor

- Ultimate Vacuum: Less than 40 mTorr

- 2 inches magnetron cathode

- Electronic shutter

- Electronic leak valve

- Transfer the curves and sputtering process data by USB port to PC

- Quartz crystal sensors

- Planetary Sample Rotation

- Spare glass chamber

- Sputtering targets

- Sealing gaskets