-

micrux

micrux

-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

AWSensors

AWSensors

-

Automatic Research

Automatic Research

-

BASI

BASI

-

BRS

BRS

-

BWB Technologies

BWB Technologies

-

Cmc

Cmc

-

CTRL

CTRL

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Coxem

Coxem

-

C-Tech

C-Tech

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

ECH

ECH

-

Elsys

Elsys

-

Enervac

Enervac

-

Enapter

Enapter

-

ELVEFLOW

ELVEFLOW

-

EA Technology

EA Technology

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Electrothermal

Electrothermal

-

FASTEC

FASTEC

-

GE

GE

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HTW

HTW

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

Labnics

Labnics

-

Ida

Ida

-

LIQUID

LIQUID

-

Instytut Fotonowy

Instytut Fotonowy

-

KEHUA TECH

KEHUA TECH

-

JGG

JGG

-

HVPD

HVPD

-

Jenway

Jenway

-

Jacomex

Jacomex

-

IVIUM

IVIUM

-

ndb

ndb

-

OZM

OZM

-

Redoxme

Redoxme

-

Serstech

Serstech

-

SATIR

SATIR

-

VacCoat

VacCoat

-

Zurich

Zurich

- micrux

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- AWSensors

- Automatic Research

- BASI

- BRS

- BWB Technologies

- Cmc

- CTRL

- CALMET

- CHECKLINE

- Coxem

- C-Tech

- DV Power

- DANATRONICS

- ECH

- Elsys

- Enervac

- Enapter

- ELVEFLOW

- EA Technology

- EL-CELL

- ENERGY SUPPORT

- Electrothermal

- FASTEC

- GE

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GREENLIGHT

- GRZ

- HTW

- HIGH SENSE SOLUTIONSHTW

- HUBER

- Labnics

- Ida

- LIQUID

- Instytut Fotonowy

- KEHUA TECH

- JGG

- HVPD

- Jenway

- Jacomex

- IVIUM

- ndb

- OZM

- Redoxme

- Serstech

- SATIR

- VacCoat

- Zurich

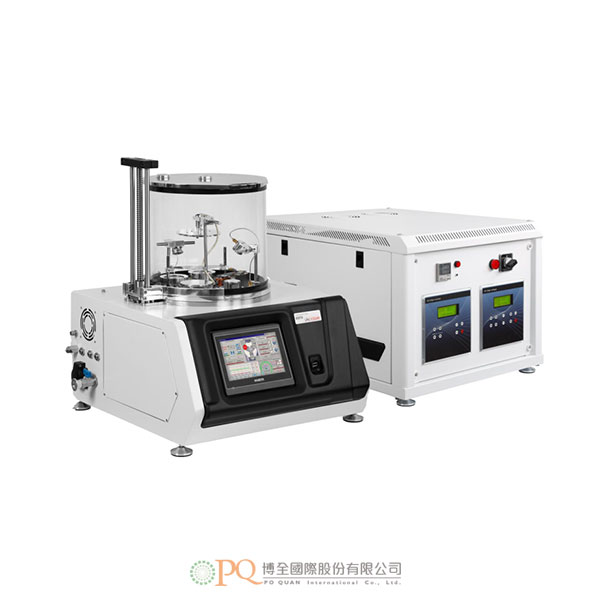

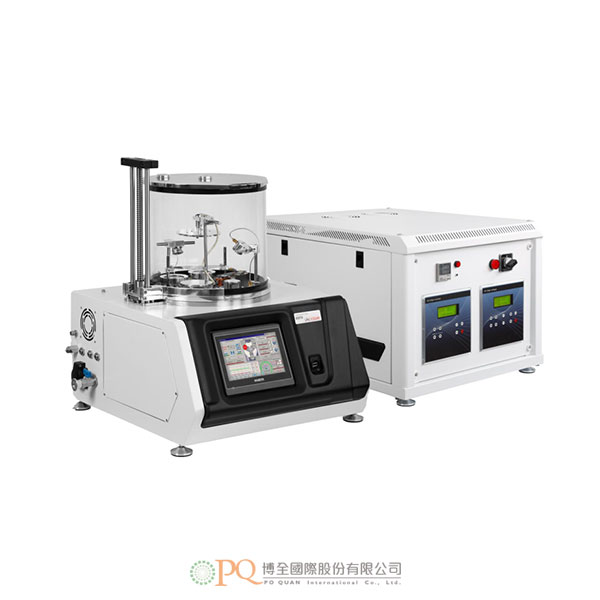

用於手套箱的濺射鍍膜機和熱蒸發儀

SPUTTER COATER AND THERMAL EVAPORATOR FOR GLOVE BOX 型號:DST2-TG-

雙靶渦輪泵濺射鍍膜機和手套箱用熱蒸鍍器DST2-TG 是一種多真空鍍膜系統,它將熱蒸鍍器和濺射鍍膜機整合在一個小型的台式系統中,可通過Wi- Fi 連接進行遠端系統控制,並可通過觸控螢幕和電腦進行控制。該高真空系統適用於多種材料的沉積。雙磁控靶台濺射鍍膜機可在蒸鍍和濺射沉積之間輕鬆切換,用於製備多層塗層。

手套箱系統可為敏感材料提供一個受保護的環境,防止與空氣或濕氣接觸,避免不必要的相互作用。帶手套箱的DST2-TG 高真空鍍膜系統可在惰性氣體環境和高度可控的腔室環境下,在沉積過程前後安全、清潔地處理基底,有助於在高真空條件下實現高純度薄層沉積。

應用

磁控濺射鍍膜機 DST2-TG 配備了一個大腔體(直徑 300 mm)和兩個直徑 2 英寸的水冷陰極,適合長時間沉積。DST2-TG 是用於濺射、碳纖維和金屬蒸鍍的單一平台。用於手套箱的台式濺射鍍膜機可以濺射半導體、電介質和金屬靶材。濺射陰極和熱蒸鍍用金屬舟可以安裝在一起,也可以互換,總共有三種沉積源可供選擇。利用碳纖維也可以實現碳沉積。

這款高精度真空鍍膜系統是半自動/全自動的,配備一個7 英寸彩色觸控螢幕面板,其友好的人機界面可輕易操控和調整沉積過程數據。面板上的功能還可通過Wi-Fi 連接在電腦上操控。另外,真空和鍍膜順序訊息可以在觸控螢幕上以數字資料或曲線的形式顯示,最後300 次鍍資訊都可儲存在歷史紀錄頁上。

用於手套箱的濺射鍍膜機和熱蒸鍍器可配備的選購裝置,包括 :

- 帶有自動調節匹配器的射頻電源,可將射頻濺射過程中的反射功率降至最低。

- 電漿清洗機,用於在薄膜沉積前清除基底表面的有機物。

應用影片 三靶濺射鍍膜機 DST3-A 的工作原理? VacCoat的濺射鍍膜機如何工作? -

- Safe and clean substrate handling before or after a deposition process under inert gas atmosphere in the glove box mounted chamber .

- Ultimate Vacuum: Less than 8x10-6 Torr .

- Highly controllable chamber environment and high purity thin layer deposition inside the glove box.

- Easy and quick target installation without need to target holder .

- Improved heat conduction utilizing targets with backing plate .

- Independent sputtering control rate for each cathode to produce fine grain structures .

- Automatic safe control of the cathode's temperatures to protect the life time of the magnets .

- Data is rapidly registered by using fully automatic touch screen control .

- Two precision Mass Flow meter (MFC) for fine control of vacuum and pressure .

- Records and plots coating parameters graphs.

- Transfers curves and deposition process data by a USB port or via Wi-Fi connection to PC .

- 0- 1200 V, 0-500 mA DC power supply .

- Utilities: 220V-110V, 50/60HZ- 16/25A.

- Instrument Dimensions: 550 Width x 600 Depth x 600 Height mm .

- Net Weight:120kg (pump, rack and instrument case) .

Accessories

- Quartz crystal sensor .

- Spare glass chamber .

- Sputtering targets .

- Sealing gaskets .

-

The DST2-TG, Double Target Turbo Pumped Sputter Coater and Thermal Evaporator for Glove Box Use, is a multi-vacuum coater system that combines thermal evaporator and sputter coater in one single compact desktop system with remote system control through a Wi-Fi connection, controllable by both touch screen and PC. The high vacuum system is suitable for the deposition of a wide range of materials. Double magnetron target desk sputter coater can easily switch between evaporation and sputtering deposition for the preparation of multilayer coatings.

Glove box systems provide a protected environment for sensitive material, preventing any contact with air or humidity and unwanted interactions. DST2-TG high-vacuum coating system with glove box offers safe and clean substrate handling before or after a deposition process under inert gas atmosphere, and a highly controllable chamber environment, contributing to high purity thin layer deposition under high vacuum conditions.

Applications

The DST2-TG, Magnetron Desk Sputter Coater, is equipped with a large chamber (300 mm diameter) and two 2” diameter water-cooled cathodes which make it suitable for long-time deposition. The DST2-TG is a single platform for sputtering, carbon fiber, and metal evaporation. The desk sputter coater for glove box can sputter semiconductors, dielectrics, and metal targets. Sputtering cathodes and thermal evaporation boats could be installed together or interchangeably, with an overall three deposition sources accessible. Carbon deposition is also made possible by utilizing carbon fiber.

This high-precision vacuum coating system is semi/fully automated, equipped with a 7” colored touch-screen panel using user-friendly software to control and adjust the deposition process data. The panel window is also made available on pc through a Wi-Fi connection. The vacuum and coating sequence information can be observed as digital data or curves on the touch screen and the last 300 coatings are saved on the history page.

The sputter coater and thermal evaporator for glove box can be equipped with optional facilities including:

- RF power supply with an auto-adjustable matching box which minimizes the reflected power in the RF sputtering process.

- Plasma cleaner for removing organic matter from the substrate surface before thin film deposition.

How Triple Target Sputter Coater DST3-A Works? How Does Our Sputter Coater Work? -

- Safe and clean substrate handling before or after a deposition process under inert gas atmosphere in the glove box mounted chamber .

- Ultimate Vacuum: Less than 8x10-6 Torr .

- Highly controllable chamber environment and high purity thin layer deposition inside the glove box.

- Easy and quick target installation without need to target holder .

- Improved heat conduction utilizing targets with backing plate .

- Independent sputtering control rate for each cathode to produce fine grain structures .

- Automatic safe control of the cathode's temperatures to protect the life time of the magnets .

- Data is rapidly registered by using fully automatic touch screen control .

- Two precision Mass Flow meter (MFC) for fine control of vacuum and pressure .

- Records and plots coating parameters graphs.

- Transfers curves and deposition process data by a USB port or via Wi-Fi connection to PC .

- 0- 1200 V, 0-500 mA DC power supply .

- Utilities: 220V-110V, 50/60HZ- 16/25A.

- Instrument Dimensions: 550 Width x 600 Depth x 600 Height mm .

- Net Weight:120kg (pump, rack and instrument case) .

Accessories

- Quartz crystal sensor .

- Spare glass chamber .

- Sputtering targets .

- Sealing gaskets .