-

micrux

micrux

-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

AWSensors

AWSensors

-

Automatic Research

Automatic Research

-

BASI

BASI

-

BRS

BRS

-

BWB Technologies

BWB Technologies

-

Cmc

Cmc

-

CTRL

CTRL

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Coxem

Coxem

-

C-Tech

C-Tech

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

ECH

ECH

-

Elsys

Elsys

-

Enervac

Enervac

-

Enapter

Enapter

-

ELVEFLOW

ELVEFLOW

-

EA Technology

EA Technology

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Electrothermal

Electrothermal

-

FASTEC

FASTEC

-

GE

GE

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HTW

HTW

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

Labnics

Labnics

-

Ida

Ida

-

LIQUID

LIQUID

-

Instytut Fotonowy

Instytut Fotonowy

-

KEHUA TECH

KEHUA TECH

-

JGG

JGG

-

HVPD

HVPD

-

Jenway

Jenway

-

Jacomex

Jacomex

-

IVIUM

IVIUM

-

ndb

ndb

-

OZM

OZM

-

Redoxme

Redoxme

-

Serstech

Serstech

-

SATIR

SATIR

-

VacCoat

VacCoat

-

Zurich

Zurich

- micrux

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- AWSensors

- Automatic Research

- BASI

- BRS

- BWB Technologies

- Cmc

- CTRL

- CALMET

- CHECKLINE

- Coxem

- C-Tech

- DV Power

- DANATRONICS

- ECH

- Elsys

- Enervac

- Enapter

- ELVEFLOW

- EA Technology

- EL-CELL

- ENERGY SUPPORT

- Electrothermal

- FASTEC

- GE

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GREENLIGHT

- GRZ

- HTW

- HIGH SENSE SOLUTIONSHTW

- HUBER

- Labnics

- Ida

- LIQUID

- Instytut Fotonowy

- KEHUA TECH

- JGG

- HVPD

- Jenway

- Jacomex

- IVIUM

- ndb

- OZM

- Redoxme

- Serstech

- SATIR

- VacCoat

- Zurich

高真空度熱蒸鍍系統

HIGH VACUUM THERMAL EVAPORATOR 型號:DTE-

是一種台式熱蒸鍍系統,用於在基底上沉積薄層材料,以進行研究和電子顯微鏡調查。DTE 被配置為適用於樣品蒸鍍實驗的材料蒸鍍器。這種低成本、小腔室和高真空系統非常適合惰性金屬和氧化金屬的短時間沉積。

熱蒸鍍

DTE 配備了大電流電源和低電壓(電阻式)熱蒸鍍平台,適合各種熱蒸鍍應用。該系統可將多種材料受控地熱蒸鍍到基底上。

單個熱源支架上可安裝不同類型的熱蒸鍍源(舟型、籃型與線圈型)。該系統配備 1.2 kW大電流直流電源,可以在不同的表面上沉積一層薄薄的蒸鍍材料,以適應不同的應用,例如 SEM 樣品製備。

DTE 的特點

硬體

- 材料蒸鍍半自動控制。

- 配備獨立的DC高電流電源(最大 12V,100A)。

- 直徑為 170 mm的Borosilicate-SST真空室。

- 內置渦輪泵(Leybold 90 升/秒),真空度高。

- 雙級旋轉式(可選隔膜式或渦旋式)前級泵。

- 石英晶體監測系統,用於實時厚度測量(精度 1 nm)。

- 電子快門。

- 兩個用於熱源插入的大電流電動饋通裝置。

- 可移動熱源支架,可採用向上或向下沉積配置。

- 自動排氣閥。

- 全量程真空計。

- 腔室引線的 S-Clip 樣品支架。

- 底板上的 2 英寸旋轉樣品支架(可選)。

- 可調節樣品旋轉、高度和傾斜度(適用於可選的 2 英寸樣品支架)。

自動化

- 視覺化的觸控螢幕,可控制真空過程和設備操作。

- 友善的用戶軟體介面,並可通過網路更新。電子快門。

清潔真空

- 真空室的外徑為 170 mm,高為 140 mm。

- DTE 配備了一個內部安裝的 90 L/s渦輪分子泵,

由一個 6m3/h的雙級旋轉葉片泵(可選)提供支持。

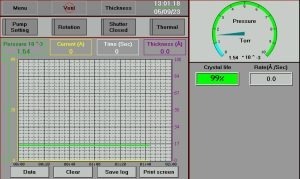

觸摸屏控制

DTE 配備一個 7 英寸彩色觸控螢幕面板,其友好的人機界面可輕易操控和調整沉積過程數據。

真空和鍍膜順序訊息可以在觸控螢幕上以數字資料或曲線的形式顯示,最後 300 次濺鍍資訊都可儲存在歷史紀錄頁上。樣品支架

DTE 沉積系統可實現向上和向下配置的金屬蒸鍍。

- 向上沉積: 將材料裝入舟型的承載器,並將樣品固定

- 向下沉積: 將少量所需材料裝入底板上帶有旋轉樣品支架(可選)的籃型的承載器中。

DTE 操作要求

DTE 是一種腔室較小的沉積系統,是一種結構緊湊、重量輕、抽真空快、成本低的鍍膜設備。

儘管如此,由於其腔體較小,還是有一些關於該設備的注意事項:- DTE 是短期薄膜塗層的理想選擇,而長期厚層沉積可能會損壞腔室。

- 該設備非常適合蒸鍍溫度較低的源材料的沉積。

- 旋轉基底支架的最大樣品直徑不能超過 2 英寸。

應用

- 金屬薄膜

- 奈米與微電子

- 太陽能電池應用

- 薄膜感測器

- 用於 SEM 和 FE-SEM 樣品製備的細顆粒結構沉積。

- 用於 SEM 樣品製備的閃蒸模式碳纖維蒸鍍。

-

- Ultimate Vacuum: Less than 4×10-6 Torr.

- Low-duration deposition process.

- Records and plots parameters displayed on the touch screen.

- Transfers curves and deposition process data by a USB port to PC.

- 0-12 V, 0-100 A DC high-current power supply.

- Utilities: 220V-110V, 50/60HZ- 6/8A.

- Instrument Dimensions: 450 Width × 450 Depth × 500 Height mm (without Rack).

- Net Weight: 30 kg (without backing pump).

The DTE has the following options and accessories:- Quartz crystal sensor.

- Spare glass chamber.

- Sealing gaskets.

- Boats and baskets.

-

DTE is a Desktop Thermal Evaporator system to deposit thin layers of materials on the substrate for research purposes and investigation by electron microscopy. DTE is configured as a material evaporator suitable for sample evaporant experiments. This low-budget, small chamber, and high-vacuum system is ideal for short time deposition of noble and oxidizing metals.

hermal Evaporation

DTE is equipped with a high current power supply and low-voltage (resistive) thermal evaporation platform suitable for a wide variety of thermal evaporation applications. The system allows controlled thermal evaporation of a wide range of materials onto the substrate. Different types of thermal evaporation sources (boat, basket, and coil) can be installed on the single thermal source holder.

The system is equipped with a 1.2 kW high-current DC power supply. The system can deposit a thin layer of the evaporant material on different surfaces for different applications, such as SEM sample preparation.

Features of DTE

Hardware- Material evaporation semi-automatic control.

- Equipped with a separate DC high-current power supply (max. 12V, 100A).

- 170 mm diameter Borosilicate-SST vacuum chamber.

- High vacuum level with built-in turbo pump (Leybold 90 l/s).

- Two-stage rotary (optional diaphragm or scroll) backing pump.

- Quartz crystal monitoring system for real time thickness measurement (1 nm precision).

- Electronic shutter.

- Two high-current electric feed-throughs for thermal source insertion.

- Movable thermal source holder with possible upward or downward deposition configurations.

- Automatic venting valve.

- Full range vacuum gauge.

- S-Clip sample holder on the chamber lead.

- 2-inch rotating sample holder on the base plate (optional).

- Sample rotation, height and tilt adjustable (for optional 2-inch sample holder)

Automation - Intuitive touch screen to control the vacuum process and device manipulation

- User friendly software, updatable via network

- Electronic shutter

Clean Vacuum - The vacuum chamber is with 170 mm OD and 140 mm H.

- The DTE is fitted with an internally mounted 90 L/s turbo molecular pump,

backed by a 6m3/h two-stage rotary vane pump (optional).

Touch Screen Control

DTE is equipped with a 7” colored touch-screen panel using user-friendly software to control the deposition process data.

The vacuum and coating sequence information can be observed as digital data or curves on the touch screen and the last 300 coatings are saved on the history page.Sample Holders

DTE deposition system enables metal evaporation in upward and downward configurations.- Upward deposition: The material is loaded in a boat source and the sample is attached to the S-Clips on the chamber lead to allow easy access.

- Downward deposition: A small amount of desired material is loaded in the basket with rotating sample holder (optional) on the baseplate.

DTE Operation Requirements

DTE is a deposition system with a small chamber, making it a compact, light-weight, quick- vacuuming, and low-budget coating device.

Although, due to its small chamber, there are some advisory notes regarding this device:- DTE is ideal for short-term thin film coatings, whereas long-term thick layer depositions may damage the chamber.

- The device is ideal for deposition of source materials with low vaporization temperature.

- The maximum sample diameter could not exceed 2 inches for rotating substrate holder.

- If these coating conditions do not suit your purpose, you can try our DTT model with a large 300 mm Dia. Chamber and three-thermal sources.

Applications

- Metal thin Films

- Nano & Microelectronic

- Solar cell applications

- Thin film sensors

- Fine grain structural deposition for SEM & FE-SEM sample preparation

- Carbon fiber evaporation in flash mode for SEM sample preparation

-

- Ultimate Vacuum: Less than 4×10-6 Torr.

- Low-duration deposition process.

- Records and plots parameters displayed on the touch screen.

- Transfers curves and deposition process data by a USB port to PC.

- 0-12 V, 0-100 A DC high-current power supply.

- Utilities: 220V-110V, 50/60HZ- 6/8A.

- Instrument Dimensions: 450 Width × 450 Depth × 500 Height mm (without Rack).

- Net Weight: 30 kg (without backing pump).

The DTE has the following options and accessories:- Quartz crystal sensor.

- Spare glass chamber.

- Sealing gaskets.

- Boats and baskets.