-

micrux

micrux

-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

AWSensors

AWSensors

-

Automatic Research

Automatic Research

-

BASI

BASI

-

BRS

BRS

-

BWB Technologies

BWB Technologies

-

Cmc

Cmc

-

CTRL

CTRL

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Coxem

Coxem

-

C-Tech

C-Tech

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

ECH

ECH

-

Elsys

Elsys

-

Enervac

Enervac

-

Enapter

Enapter

-

ELVEFLOW

ELVEFLOW

-

EA Technology

EA Technology

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Electrothermal

Electrothermal

-

FASTEC

FASTEC

-

GE

GE

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HTW

HTW

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

Labnics

Labnics

-

Ida

Ida

-

LIQUID

LIQUID

-

Instytut Fotonowy

Instytut Fotonowy

-

KEHUA TECH

KEHUA TECH

-

JGG

JGG

-

HVPD

HVPD

-

Jenway

Jenway

-

Jacomex

Jacomex

-

IVIUM

IVIUM

-

ndb

ndb

-

OZM

OZM

-

Redoxme

Redoxme

-

Serstech

Serstech

-

SATIR

SATIR

-

VacCoat

VacCoat

-

Zurich

Zurich

- micrux

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- AWSensors

- Automatic Research

- BASI

- BRS

- BWB Technologies

- Cmc

- CTRL

- CALMET

- CHECKLINE

- Coxem

- C-Tech

- DV Power

- DANATRONICS

- ECH

- Elsys

- Enervac

- Enapter

- ELVEFLOW

- EA Technology

- EL-CELL

- ENERGY SUPPORT

- Electrothermal

- FASTEC

- GE

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GREENLIGHT

- GRZ

- HTW

- HIGH SENSE SOLUTIONSHTW

- HUBER

- Labnics

- Ida

- LIQUID

- Instytut Fotonowy

- KEHUA TECH

- JGG

- HVPD

- Jenway

- Jacomex

- IVIUM

- ndb

- OZM

- Redoxme

- Serstech

- SATIR

- VacCoat

- Zurich

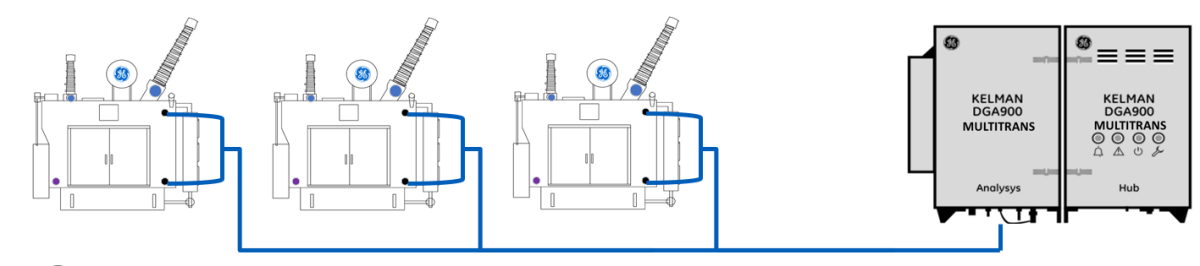

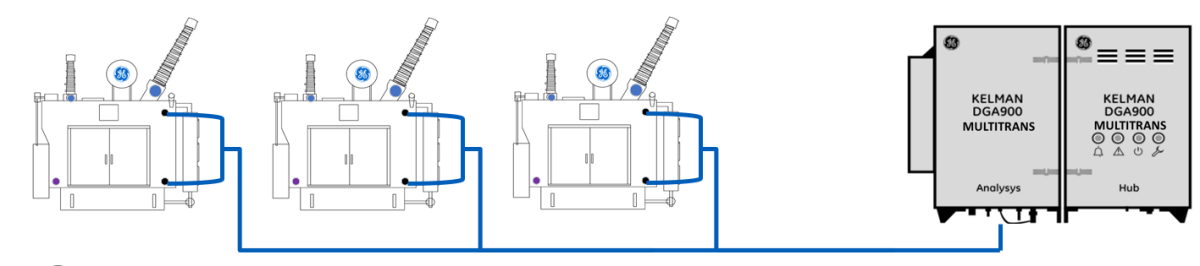

變壓器油中氣體線上監測診斷系統 – 一次監測多達3台單相變壓器

9 Gas on-line monitor for measuring DGA across multiple transformers 型號:Kelman DGA 900 MULTITRANS了解變壓器的狀況對所有電網都至關重要,而對變壓器進行線上監測也日益成為成功資產管理計劃的重要組成部分。Kelman DGA 900 MULTITRANS 提供的全面信息不僅可以避免代價高昂的故障,還能最大限度地提高資產能力。

-

Kelman DGA 900 MULTITRANS 是新一代 變壓器油中氣體線上監測診斷系統。同樣,以 DGA 900 平台為基礎,其功能超出了測量單個變壓器主油箱的範圍。

了解變壓器的狀況對所有電網都至關重要,而對變壓器進行線上監測也日益成為成功資產管理計劃的重要組成部分。Kelman DGA 900 MULTITRANS 提供的全面信息不僅可以避免代價高昂的故障,還能最大限度地提高資產能力。

DGA 900 MULTITRANS 採用第四代先進的光聲光譜檢測技術,可測量國際標準規定的所有重要故障氣體(以 ppm 為單位)以及油中的水分(%RH 和 ppm)。通過測量這些氣體,用戶可以檢測和診斷各種變壓器故障。

DGA 900 MULTITRANS很適合監控大型關鍵任務變壓器或受損變壓器。並各自安裝於3個單相變壓器的配置,用以延長資產壽命、防止意外故障並按照基於狀態的維護計劃進行管理。

-

MEASUREMENTS Technology

Automated head-space gas extraction.

Photo-acoustic spectroscopy (PAS) gas measurement.

Thin film capacitive moisture sensor.

Immersed fiber optic oxygen sensor.Frequency Configurable from once per hour to once every 4 weeks.

Faster sampling automatically triggered upon alert level reached.

"Rapid Mode" provides a rapid indication of the evolution of the gasses indicated below in ~30 minutes.Range

LDL UDL Accuracy* Repeatability Response Time*** Rapid Mode Hydrogen (H₂) 5 5,000 ppm ± LDL or ±5 % < 3 % > 90 % • Carb. Monox. (CO) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % • Methane (CH₄) 2 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Acetylene (C₂H₂) 0.5 50,000 ppm ± LDL or ±3 % < 2 % > 95 % • Ethylene (C₂H₄) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Carb. Diox. (CO₂) 20 50,000 ppm ± LDL or ±3 % < 3 % > 95 % • Ethane (C₂H6) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Oxygen (O₂) 100 50,000 ppm ± LDL or ±5 % < 2 % • Nitrogen (N₂) ** 10,000 100,000 ppm ± LDL or ±15 % Moisture (H₂O) 0 100 % RS (in ppm) ± 3 % ppm < 3 % • *whichever is greater. Accuracy quoted is the accuracy of the detectors during calibration. Gas-in-oil measurement may be affected by oil type and condition.

Repeatability as measured from final production test data.

** N₂ value is calculated and available on free-breathing transformers only.

*** Time Response (typical): % of value after 1 measurement cycle.FEATURES Display

4 x Sunlight visible LED arrays

Backlit 7” inch color resistive touch screen (800 x 480)

Embedded secure webserver (https)Analogue Input 1 x Standard for split core load CT sensor Digital Output

6 x Standard customer programmable dry contact relays (type

C, SPDT), NO/NC, 10A @250Vac resistive load, 8A @30Vdc

resistive load

1 x Standard service alarm relay

1 x Standard watchdog relayDigital Communications / Protocols 1 x Modbus® over RS485 / TCP/IP as standard

1 x Standard 1Gb Ethernet (RJ45)

Option: DNP3.0 over RS485 or TCP/IP

Option: IEC 61850 Edition 2

Option: ST/SC Multi-mode fiber converters

Option: GPRS/UMTS/HSPA+ modemADD-ONS † Option – Bushing Monitoring 3 Phase Transformers Up to 6 x Bushing adaptors ordered separately

Standard: Bushing HV (3 Bushings)

Option: Bushings HV & LV (6 Bushings)

Option: Inputs for phase to ground reference voltage

All sensors supplied unless notedMECHANICAL Analysis Unit Hub Unit Dimensions 600 x 484 x 330 mm 600 x 380 x 330 mm 23.6 x 19.1 x 13.0 in 23.6 x 15.0 x 13.0 in Weight 32 kg / 70.5 lb 18.5 kg / 40.8 lb POWER REQUIREMENTS AC Nominal 100-240 Vac (Range 85-264), 4A

DC Nominal 100-250 Vdc (Range 90-300)OPTIONS Mounting stand and Sun canopy

Longer umbilical cable between unitsENVIRONMENT Operating Conditions

mbient temperature:-40 °C to +55 °C (-40 °F to +131 °F)

Ambient humidity:0-95 % RH, non-condensing

Oil temp at valve††:-20 °C to +120 °C (-4 °F to +248 °F)Enclosure IP56 certified

Standard: Powder coated marine grade 2 mm aluminium (RAL9002)

Option: Unpainted 316 Stainless Steel †Bushing monitoring will be available in future releases

††Based on testing carried out using Voltesso™ 35 mineral oil, over a ¼” pipe run of 10 metres or less from oil supply or return valve to monitor connection point and

on transformer oil supply valve volumes of 200 ml or less. For oil temperatures colder than -20 ºC GE recommends the use of heat trace cabling on piping -

The Kelman DGA 900 MULTITRANS is the next generation 9-gas on-line transformer multi gas DGA (Diagnostic Gas Analyzer) monitor. Built from the DGA 900 platform, the Multitrans extends the capability beyond measuring a single transformer main oil tank.

Knowledge of the condition of transformers is essential for all electrical networks and on-line monitoring of transformers is an increasingly vital component of successful asset management programs. The comprehensive information provided by the Kelman DGA 900 MULTITRANS not only allows expensive failures to be avoided but enables asset capabilities to be maximized.

Using our 4th generation of advanced photo-acoustic detection technology, the DGA 900 MULTITRANS measures all significant fault gases (in ppm) as outlined by international standards as well as moisture in oil (%RH & ppm). The measurement of these gases allows the user to detect and diagnose a complete range of transformer faults.

The information provided by multi-gas on-line DGA allows asset capabilities to be maximized and expensive failures to be avoided.

MULTITRANS is best suited for monitoring large, system critical or already compromised transformers, arranged in a 3 single phase tank configuration, with a view to extending asset life, preventing unexpected failure and operating on a condition-based maintenance schedule.

-

MEASUREMENTS Technology

Automated head-space gas extraction.

Photo-acoustic spectroscopy (PAS) gas measurement.

Thin film capacitive moisture sensor.

Immersed fiber optic oxygen sensor.Frequency Configurable from once per hour to once every 4 weeks.

Faster sampling automatically triggered upon alert level reached.

"Rapid Mode" provides a rapid indication of the evolution of the gasses indicated below in ~30 minutes.Range

LDL UDL Accuracy* Repeatability Response Time*** Rapid Mode Hydrogen (H₂) 5 5,000 ppm ± LDL or ±5 % < 3 % > 90 % • Carb. Monox. (CO) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % • Methane (CH₄) 2 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Acetylene (C₂H₂) 0.5 50,000 ppm ± LDL or ±3 % < 2 % > 95 % • Ethylene (C₂H₄) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Carb. Diox. (CO₂) 20 50,000 ppm ± LDL or ±3 % < 3 % > 95 % • Ethane (C₂H6) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Oxygen (O₂) 100 50,000 ppm ± LDL or ±5 % < 2 % • Nitrogen (N₂) ** 10,000 100,000 ppm ± LDL or ±15 % Moisture (H₂O) 0 100 % RS (in ppm) ± 3 % ppm < 3 % • *whichever is greater. Accuracy quoted is the accuracy of the detectors during calibration. Gas-in-oil measurement may be affected by oil type and condition.

Repeatability as measured from final production test data.

** N₂ value is calculated and available on free-breathing transformers only.

*** Time Response (typical): % of value after 1 measurement cycle.FEATURES Display

4 x Sunlight visible LED arrays

Backlit 7” inch color resistive touch screen (800 x 480)

Embedded secure webserver (https)Analogue Input 1 x Standard for split core load CT sensor Digital Output

6 x Standard customer programmable dry contact relays (type

C, SPDT), NO/NC, 10A @250Vac resistive load, 8A @30Vdc

resistive load

1 x Standard service alarm relay

1 x Standard watchdog relayDigital Communications / Protocols 1 x Modbus® over RS485 / TCP/IP as standard

1 x Standard 1Gb Ethernet (RJ45)

Option: DNP3.0 over RS485 or TCP/IP

Option: IEC 61850 Edition 2

Option: ST/SC Multi-mode fiber converters

Option: GPRS/UMTS/HSPA+ modemADD-ONS † Option – Bushing Monitoring 3 Phase Transformers Up to 6 x Bushing adaptors ordered separately

Standard: Bushing HV (3 Bushings)

Option: Bushings HV & LV (6 Bushings)

Option: Inputs for phase to ground reference voltage

All sensors supplied unless notedMECHANICAL Analysis Unit Hub Unit Dimensions 600 x 484 x 330 mm 600 x 380 x 330 mm 23.6 x 19.1 x 13.0 in 23.6 x 15.0 x 13.0 in Weight 32 kg / 70.5 lb 18.5 kg / 40.8 lb POWER REQUIREMENTS AC Nominal 100-240 Vac (Range 85-264), 4A

DC Nominal 100-250 Vdc (Range 90-300)OPTIONS Mounting stand and Sun canopy

Longer umbilical cable between unitsENVIRONMENT Operating Conditions

mbient temperature:-40 °C to +55 °C (-40 °F to +131 °F)

Ambient humidity:0-95 % RH, non-condensing

Oil temp at valve††:-20 °C to +120 °C (-4 °F to +248 °F)Enclosure IP56 certified

Standard: Powder coated marine grade 2 mm aluminium (RAL9002)

Option: Unpainted 316 Stainless Steel †Bushing monitoring will be available in future releases

††Based on testing carried out using Voltesso™ 35 mineral oil, over a ¼” pipe run of 10 metres or less from oil supply or return valve to monitor connection point and

on transformer oil supply valve volumes of 200 ml or less. For oil temperatures colder than -20 ºC GE recommends the use of heat trace cabling on piping