-

micrux

micrux

-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

AWSensors

AWSensors

-

Automatic Research

Automatic Research

-

BASI

BASI

-

BRS

BRS

-

BWB Technologies

BWB Technologies

-

Cmc

Cmc

-

CTRL

CTRL

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Coxem

Coxem

-

C-Tech

C-Tech

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

ECH

ECH

-

Elsys

Elsys

-

Enervac

Enervac

-

Enapter

Enapter

-

ELVEFLOW

ELVEFLOW

-

EA Technology

EA Technology

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Electrothermal

Electrothermal

-

FASTEC

FASTEC

-

GE

GE

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HTW

HTW

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

Labnics

Labnics

-

Ida

Ida

-

LIQUID

LIQUID

-

Instytut Fotonowy

Instytut Fotonowy

-

KEHUA TECH

KEHUA TECH

-

JGG

JGG

-

HVPD

HVPD

-

Jenway

Jenway

-

Jacomex

Jacomex

-

IVIUM

IVIUM

-

ndb

ndb

-

OZM

OZM

-

Redoxme

Redoxme

-

Serstech

Serstech

-

SATIR

SATIR

-

VacCoat

VacCoat

-

Zurich

Zurich

- micrux

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- AWSensors

- Automatic Research

- BASI

- BRS

- BWB Technologies

- Cmc

- CTRL

- CALMET

- CHECKLINE

- Coxem

- C-Tech

- DV Power

- DANATRONICS

- ECH

- Elsys

- Enervac

- Enapter

- ELVEFLOW

- EA Technology

- EL-CELL

- ENERGY SUPPORT

- Electrothermal

- FASTEC

- GE

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GREENLIGHT

- GRZ

- HTW

- HIGH SENSE SOLUTIONSHTW

- HUBER

- Labnics

- Ida

- LIQUID

- Instytut Fotonowy

- KEHUA TECH

- JGG

- HVPD

- Jenway

- Jacomex

- IVIUM

- ndb

- OZM

- Redoxme

- Serstech

- SATIR

- VacCoat

- Zurich

變壓器油中氣體線上監測診斷系統

9 Gas on-line monitor for measuring DGA on OLTC transformers 型號:Kelman DGA 900 TAPTRANS-

監測變壓器及有載分接頭切換器的油中氣體/水分

對變壓器狀況的了解對所有的電氣網路都是至關重要的,變壓器的線上監測對於成功的資產管理計劃愈益重要。Kelman™ DGA 900 TAPTRANS所提供的全面信息能幫助我們將有用的資產發揮到最大的價值, 並避免代價高昂的故障狀況發生。

Kelman DGA 900 TAPTRANS是一項專利設備,專門為帶有有載分接頭切換器(OLTC)的變壓器設計。當前OLTC 被認證為變壓器最脆弱的結構之一,並且佔計劃外停電的很大一部分。它提供油中9種溶解氣體與水分監測,可以相繼測量主油箱、選擇器及切換器油室。採用光聲光譜偵測系統,可測量不同油箱內發現的高、低濃度氣體,而不會發生交叉污染兼具有實驗室的精度和可再現性水準,更可確保您的資產設備安全性。

完整 9 種油中氣體採樣和分析可以在單個油槽上每小時進行一次,若同時三個油槽都連接起來,則最多每三小時一次。

主要優勢

主要優點

- 模組化和可改裝的架構,能更適應不同的現場條件與應用。

- 對變壓器狀況和安全運行提供廣泛的長遠洞察力。

- 為驗證和深入的故障分析提供相關的數據。

- 使用基於內置網頁的 HMI 和本地彩色屏幕進行圖形化展示。

- 與GE著名的Perception™ Fleet資產管理軟體相互結合。

- 來自唯一擁有15年PAS經驗和超過15,000台安裝基礎的供應商。

應用

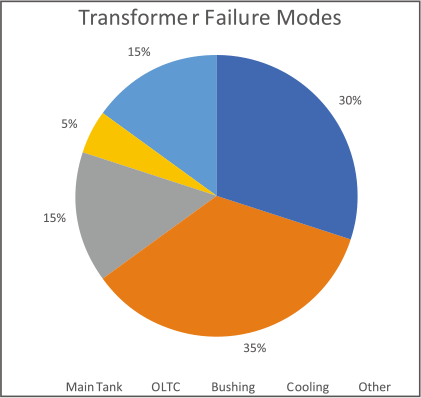

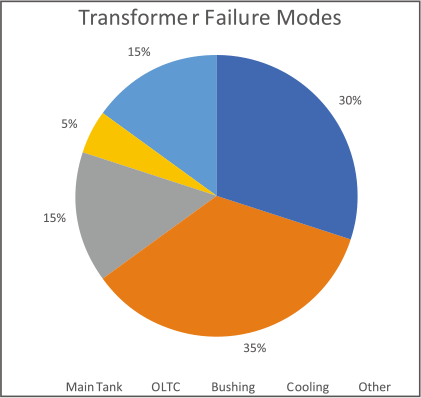

雖然線上 DGA 現在被廣泛接受為評估變壓器狀況的最有效方法,但它並未涵蓋所有可能的問題來源。像有載分接頭切換器(OLTC)、冷卻系統或套管這樣的次系統如果不加以監控,就會產生自己的問題。在以變壓器故障類型,主油槽與有載分接頭切換器(OLTC)事故佔比就高達65%,這對於安全運行都至關重要的。

Kelman DGA 900 TAPTRANS最適合於監測大型、關鍵任務的變壓器或受損的變壓器,同時在電力系統運轉中,為了確保系統電壓之品質,變電所之變壓器一般皆使用有載分接頭切換器(On-Load Tap Changer,OLTC),維持輸出電壓之穩定的重要部件監測,以期延長其壽命並防止任何意外故障。

經驗證的技術

- 對3個油源的9 種氣體與水分的實驗室級現場測量。

- 將主油箱和選擇器油箱與切換油箱分開,以避免任何污染的風險。

- 採用GE 第四代光聲光譜偵測技術,具有更低的偵測限值及更高的精度。

- 無需載流或校正氣體耗材。

- 快至每小時1 次完整的DGA 分析;新的“快速模式”,可於30分鐘內提供重要氣體監測結果。

應用

- 工業應用,如電弧爐、鑄造廠和造紙廠。

- 輸電系統。

- 再生能源應用,如風力發電站和太陽能發電廠。

套管和局部放電監測

- 測量由套管老化引起的電容 C1 和/或功率因數 (Tan delta) 的變化。

- 避免大範圍的事故損害,甚至變壓器的全損。

- 使用相同的套管分接頭裝置檢測變壓器內部的電氣局部放電事件。

- 採用脈衝極性鑑別減少PD 的外在干擾和PRPD相位分析法 繪製二維 PD 活動的演變。

OLTC 監控

- OLTC的切換操作次數。

- OLTC的位置紀錄。

- OLTC-主油箱的油溫差。

- OLTC的馬達轉矩。

-

MEASUREMENTS Technology

Automated head-space gas extraction.

Photo-acoustic spectroscopy (PAS) gas measurement.

Thin film capacitive moisture sensor.

Immersed fiber optic oxygen sensorFrequency Configurable from once per hour to once every 4 weeks.

Faster sampling automatically triggered upon alert level reached.

"Rapid Mode" provides a rapid indication of the evolution of the gasses indicated below in ~30 minutes.Range

LDL UDL Accuracy* Repeatability Response Time*** Rapid Mode Hydrogen (H₂) 5 5,000 ppm ± LDL or ±5 % < 3 % > 90 % • Carb. Monox. (CO) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % • Methane (CH₄) 2 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Acetylene (C₂H₂) 0.5 50,000 ppm ± LDL or ±3 % < 2 % > 95 % • Ethylene (C₂H₄) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Carb. Diox. (CO₂) 20 50,000 ppm ± LDL or ±3 % < 3 % > 95 % • Ethane (C₂H6) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Oxygen (O₂) 100 50,000 ppm ± LDL or ±5 % < 2 % • Nitrogen (N₂) ** 10,000 100,000 ppm ± LDL or ±15 % Moisture (H₂O) 0 100 % RS (in ppm) ± 3 % ppm < 3 % • FEATURES Display

4 x Sunlight visible LED arrays

Backlit 7” inch color resistive touch screen (800 x 480)

Embedded secure webserver (https)Analogue Input 1 x Standard for split core load CT sensor Digital Output

6 x Standard customer programmable dry contact relays (type C, SPDT), NO/NC, 10A@ 250Vac resistive load, 10A@ 30Vdc resistive load

1 x Standard service alarm relay

1 x Standard watchdog relayDigital Communications / Protocols 1 x Modbus® over RS485 / TCP/IP as standard

1 x Standard 1Gb Ethernet (RJ45)

Option: DNP3.0 over RS485 or TCP/IP

Option: IEC 61850 Edition 2

Option: ST/SC Multi-mode fiber converters

Option: GPRS/UMTS/HSPA+ modemADD-ONS † Option – OLTC Monitoring † Standard: Motor torque sensor

Standard: 2 x Magnetic mounted temperature sensor

Standard: 4 – 20mA or Resistive OLTC position input (sensor not supplied)Option – Bushing Monitoring 3 Phase Transformers

Up to 6 x Bushing adaptors ordered separately

Standard: Bushing HV (3 Bushings)

Option: Bushings HV & LV (6 Bushings)

Option: Inputs for phase to ground reference voltage

All sensors supplied unless notedMECHANICAL Analysis Unit Hub Unit Dimensions 600 x 484 x 330 mm 600 x 380 x 330 mm 23.6 x 19.1 x 13.0 in 23.6 x 15.0 x 13.0 in Weight 37 kg / 81.6 lb 18.5 kg / 40.8 lb POWER REQUIREMENTS AC Nominal 100-240 Vac (Range 85-264), 4A

DC Nominal 100-250 Vdc (Range 90-300)OPTIONS Mounting stand and Sun canopy

Longer umbilical cable between unitsENVIRONMENT Operating Conditions

mbient temperature:-40 °C to +55 °C (-40 °F to +131 °F)

Ambient humidity:0-95 % RH, non-condensing

Oil temp at valve††:-20 °C to +120 °C (-4 °F to +248 °F)Enclosure IP56 certified

Standard: Powder coated marine grade 2 mm aluminium (RAL9002)

Option: Unpainted 316 Stainless Steel

†OLTC and Transformer models will be available 2022

††Based on testing carried out using Voltesso™ 35 mineral oil, over a ¼” pipe run of 10 metres or less from oil supply or return valve to monitor connection point and on

transformer oil supply valve volumes of 200 ml or less. For oil temperatures colder than -20 ºC GE recommends the use of heat trace cabling on piping -

9 gas on-line OLTC DGA expandable with add-ons to a Transformer Monitoring System (TMS)

Knowledge of the condition of transformers is essential for all electrical networks and on-line monitoring of transformers is an increasingly vital component of successful asset management programs. The comprehensive information provided by the Kelman™ DGA 900 TAPTRANS not only allows expensive failures to be avoided but enables asset capabilities to be maximized.

The Kelman DGA 900 TAPTRANS is a patented designed specifically for transformers with an On-Load Tap Changer (OLTC), which is recognised as one of the most vulnerable parts of the transformer and which accounts for a large portion of unplanned outages. It offers discrete multigas on-line DGA and moisture monitoring, separating the main and selector tanks from the diverter tank to avoid any risk of contamination. Utilizing photo-acoustic spectroscopy (PAS) measurement technology, well suited to field application, it provides laboratory challenging levels of precision and repeatability. Full 9 gas oil sampling and analysis can be performed as often as every hour on a single tank and up to once every three hours if all three possible oil tanks are connected.Key Benefits

- Modular and retrofittable architecture using selectable standard add-on cards

- Provides extensive remote insight into transformer condition and safe operation

- Enables correlation of data for validation and in-depth fault analysis

- Graphical presentation using built-in web-page based HMI and local color screen

- Full integration with GE’s acclaimed Perception™ Fleet asset management software

- From the only vendor with 15 years PAS experience and installed base of >15,000 units

Applications

While on-line DGA is now widely accepted as the most effective method of assessing the condition of a transformer, it does not cover all the possible sources of issues. Sub- systems like the tap changer, the cooling system or the bushings can generate their own problems if they are left unmonitored.

It is most suited for monitoring large, mission critical transformers or compromised transformers with a view to extending their life and preventing any unexpected failure.

Industrial processes where an OLTC Transformer is seen as a manufacturing tool, often dependent on an uninterruptible power supply as part of the process.

Preventing unplanned outages is vital to maintain the manufacturing process output, where failure would result in costly downtime or waste. The OLTC transformer is often used within renewable power generation where varying output needs to be compensated.Cutting Edge DGA

- Laboratory challenging field measurement of nine gases plus moisture on 3 oil sources

- Individual oil manifolds for the main and OLTC Diverter tank

- 4th generation of GE’s PAS technology delivering improved measurement accuracy with lower detection limits

- No carrier or calibration gas consumables

- Complete analysis up to once per hour and new “Rapid Mode” for critical gases in ~30 min

Applications

- Industrial OLTC applications such as arc furnaces, foundry’s, and paper mills

- Power transmission networks

- Renewable applications such as windfarms and solar plants

Bushing & PD Monitoring

- Measures the change in Capacitance C1 and/ or Power Factor (Tan delta) caused by the deterioration of the bushing

- Avoid widespread collateral damage and even total loss of transformer

- Detects electrical PD events inside the transformer using the same bushing adaptors

- Multiple noise rejection methods and graphical PRPD analysis

OLTC Monitoring

- Supervision of a key mechanical component of the transformer

- OLTC tap position recorder

- Temperature difference between tanks

- Torque used by tap changing motor

-

MEASUREMENTS Technology

Automated head-space gas extraction.

Photo-acoustic spectroscopy (PAS) gas measurement.

Thin film capacitive moisture sensor.

Immersed fiber optic oxygen sensorFrequency Configurable from once per hour to once every 4 weeks.

Faster sampling automatically triggered upon alert level reached.

"Rapid Mode" provides a rapid indication of the evolution of the gasses indicated below in ~30 minutes.Range

LDL UDL Accuracy* Repeatability Response Time*** Rapid Mode Hydrogen (H₂) 5 5,000 ppm ± LDL or ±5 % < 3 % > 90 % • Carb. Monox. (CO) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % • Methane (CH₄) 2 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Acetylene (C₂H₂) 0.5 50,000 ppm ± LDL or ±3 % < 2 % > 95 % • Ethylene (C₂H₄) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Carb. Diox. (CO₂) 20 50,000 ppm ± LDL or ±3 % < 3 % > 95 % • Ethane (C₂H6) 1 50,000 ppm ± LDL or ±3 % < 2 % > 95 % Oxygen (O₂) 100 50,000 ppm ± LDL or ±5 % < 2 % • Nitrogen (N₂) ** 10,000 100,000 ppm ± LDL or ±15 % Moisture (H₂O) 0 100 % RS (in ppm) ± 3 % ppm < 3 % • FEATURES Display

4 x Sunlight visible LED arrays

Backlit 7” inch color resistive touch screen (800 x 480)

Embedded secure webserver (https)Analogue Input 1 x Standard for split core load CT sensor Digital Output

6 x Standard customer programmable dry contact relays (type C, SPDT), NO/NC, 10A@ 250Vac resistive load, 10A@ 30Vdc resistive load

1 x Standard service alarm relay

1 x Standard watchdog relayDigital Communications / Protocols 1 x Modbus® over RS485 / TCP/IP as standard

1 x Standard 1Gb Ethernet (RJ45)

Option: DNP3.0 over RS485 or TCP/IP

Option: IEC 61850 Edition 2

Option: ST/SC Multi-mode fiber converters

Option: GPRS/UMTS/HSPA+ modemADD-ONS † Option – OLTC Monitoring † Standard: Motor torque sensor

Standard: 2 x Magnetic mounted temperature sensor

Standard: 4 – 20mA or Resistive OLTC position input (sensor not supplied)Option – Bushing Monitoring 3 Phase Transformers

Up to 6 x Bushing adaptors ordered separately

Standard: Bushing HV (3 Bushings)

Option: Bushings HV & LV (6 Bushings)

Option: Inputs for phase to ground reference voltage

All sensors supplied unless notedMECHANICAL Analysis Unit Hub Unit Dimensions 600 x 484 x 330 mm 600 x 380 x 330 mm 23.6 x 19.1 x 13.0 in 23.6 x 15.0 x 13.0 in Weight 37 kg / 81.6 lb 18.5 kg / 40.8 lb POWER REQUIREMENTS AC Nominal 100-240 Vac (Range 85-264), 4A

DC Nominal 100-250 Vdc (Range 90-300)OPTIONS Mounting stand and Sun canopy

Longer umbilical cable between unitsENVIRONMENT Operating Conditions

mbient temperature:-40 °C to +55 °C (-40 °F to +131 °F)

Ambient humidity:0-95 % RH, non-condensing

Oil temp at valve††:-20 °C to +120 °C (-4 °F to +248 °F)Enclosure IP56 certified

Standard: Powder coated marine grade 2 mm aluminium (RAL9002)

Option: Unpainted 316 Stainless Steel

†OLTC and Transformer models will be available 2022

††Based on testing carried out using Voltesso™ 35 mineral oil, over a ¼” pipe run of 10 metres or less from oil supply or return valve to monitor connection point and on

transformer oil supply valve volumes of 200 ml or less. For oil temperatures colder than -20 ºC GE recommends the use of heat trace cabling on piping