選擇品牌

-

AstroNova

AstroNova

-

AOiP

AOiP

-

ADASH

ADASH

-

Amptek

Amptek

-

Automatic Research

Automatic Research

-

AWSensors

AWSensors

-

AARONIA AG

AARONIA AG

-

BASI

BASI

-

CALMET

CALMET

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

Dioxide Materials

Dioxide Materials

-

ED & D

ED & D

-

ELVEFLOW

ELVEFLOW

-

ECH

ECH

-

Elsys

Elsys

-

EA Technology

EA Technology

-

Enapter

Enapter

-

Electrothermal

Electrothermal

-

Enervac

Enervac

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

FASTEC

FASTEC

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GRZ

GRZ

-

HVPD

HVPD

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

IVIUM

IVIUM

-

Ida

Ida

-

Instytut Fotonowy

Instytut Fotonowy

-

JGG

JGG

-

Jacomex

Jacomex

-

Jenway

Jenway

-

Kocos

Kocos

-

KEHUA TECH

KEHUA TECH

-

micrux

micrux

-

Metrel

Metrel

-

Microrad

Microrad

-

METERTEST

METERTEST

-

ndb

ndb

-

Norecs

Norecs

-

Novocontrol

Novocontrol

-

Neware

Neware

-

OKOndt Group

OKOndt Group

-

OZM

OZM

-

Pine Research

Pine Research

-

Pinflow

Pinflow

-

Redoxme

Redoxme

-

SATIR

SATIR

-

Sonel

Sonel

-

Serstech

Serstech

-

SDT

SDT

-

SENSIA

SENSIA

-

SIKA

SIKA

-

SMC

SMC

-

TANDELTA

TANDELTA

-

TENTECH

TENTECH

-

Turnkey Instruments

Turnkey Instruments

-

VacCoat

VacCoat

-

Zurich Instruments

Zurich Instruments

- AstroNova

- AOiP

- ADASH

- Amptek

- Automatic Research

- AWSensors

- AARONIA AG

- BASI

- CALMET

- DV Power

- DANATRONICS

- Dioxide Materials

- ED & D

- ELVEFLOW

- ECH

- Elsys

- EA Technology

- Enapter

- Electrothermal

- Enervac

- EL-CELL

- ENERGY SUPPORT

- FASTEC

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GRZ

- HVPD

- HIGH SENSE SOLUTIONSHTW

- HUBER

- IVIUM

- Ida

- Instytut Fotonowy

- JGG

- Jacomex

- Jenway

- Kocos

- KEHUA TECH

- micrux

- Metrel

- Microrad

- METERTEST

- ndb

- Norecs

- Novocontrol

- Neware

- OKOndt Group

- OZM

- Pine Research

- Pinflow

- Redoxme

- SATIR

- Sonel

- Serstech

- SDT

- SENSIA

- SIKA

- SMC

- TANDELTA

- TENTECH

- Turnkey Instruments

- VacCoat

- Zurich Instruments

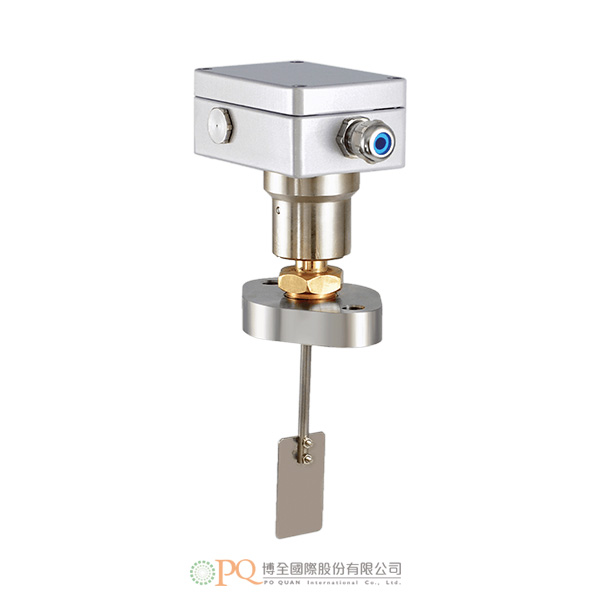

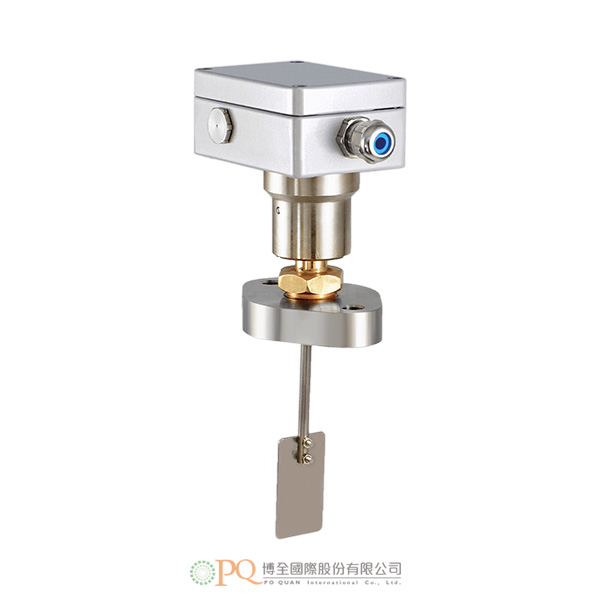

Flow switches for insertion installation / Metal version for electrical engineer

型號:Type VH501- Complies with the following technical regulations of railway application: DIN EN 60077-1:2003, DIN EN 50125-1:2014, DIN EN 50216-5:2007, DIN EN 45545-2:2016

- For oil flow monitoring

- For pipelines DN 65...DN100 (DN 25...DN 50 upon request)

- High switching currents, micro switch as signal transmitter

- Optional: Cable gland selectable on three sides, version with flange or thread

-

SIKA flow monitors monitor the liquid flow of low-viscosity media in pipelines. The SIKA paddle flow monitor VH501 is particularly suitable for oil flow monitoring in traction transformers, e.g. in the electrical industry or in rail transport.

The flowing medium hits the baffle flag attached to the end of a paddle. The paddle is deflected by the resulting dynamic pressure and actuates a micro switch.

-

Technical data Switching function Change over contact or two change over contacts Setpoint* Flanged version 6 m³/h at increasing flow for DN 65 pipes

Threaded version 10 m³/h at increasing flow for DN 80 pipesPressure rating (Test pressure) Max. 10 bar (14 bar) Process connection Flange, oval, 2 holes without O-ring groove; Flange, round, 4 holes without O-ring groove

Screw in connection G1 maleVibration proof IEC61373 4g Temperature ranges Medium -40...120 °C Ambient -40...100 °C Storage -40...100 °C Electrical data Electrical connection Direct cabeling, QC terminals 2.8 x 0.5 mm Max. contact rating 48 VDC, 1 A resistive load

110 VDC, 0.5 A resistive load / 0.2 A inductive load

250 VAC, 6 A resistive loadDegree of protection EN 60529 IP68 and IP69K Terminal box Surface finish

Impact resistance

Cable gland

Cable diameter range

Cable gland orientationPowder coated RAL9006

IK10 (10 Joule)

M16 x 1.5

4...11 mm

Location selectable on three sides* Other setpoints on request