-

AstroNova

AstroNova

-

AOiP

AOiP

-

ADASH

ADASH

-

Amptek

Amptek

-

Automatic Research

Automatic Research

-

AWSensors

AWSensors

-

AARONIA AG

AARONIA AG

-

BASI

BASI

-

CALMET

CALMET

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

Dioxide Materials

Dioxide Materials

-

ED & D

ED & D

-

ELVEFLOW

ELVEFLOW

-

ECH

ECH

-

Elsys

Elsys

-

EA Technology

EA Technology

-

Enapter

Enapter

-

Electrothermal

Electrothermal

-

Enervac

Enervac

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

FASTEC

FASTEC

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GRZ

GRZ

-

HVPD

HVPD

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

IVIUM

IVIUM

-

Ida

Ida

-

Instytut Fotonowy

Instytut Fotonowy

-

JGG

JGG

-

Jacomex

Jacomex

-

Jenway

Jenway

-

Kocos

Kocos

-

KEHUA TECH

KEHUA TECH

-

micrux

micrux

-

Metrel

Metrel

-

Microrad

Microrad

-

METERTEST

METERTEST

-

ndb

ndb

-

Norecs

Norecs

-

Novocontrol

Novocontrol

-

Neware

Neware

-

OKOndt Group

OKOndt Group

-

OZM

OZM

-

Pine Research

Pine Research

-

Pinflow

Pinflow

-

Redoxme

Redoxme

-

SATIR

SATIR

-

Sonel

Sonel

-

Serstech

Serstech

-

SDT

SDT

-

SENSIA

SENSIA

-

SIKA

SIKA

-

SMC

SMC

-

TANDELTA

TANDELTA

-

TENTECH

TENTECH

-

Turnkey Instruments

Turnkey Instruments

-

VacCoat

VacCoat

-

Zurich Instruments

Zurich Instruments

- AstroNova

- AOiP

- ADASH

- Amptek

- Automatic Research

- AWSensors

- AARONIA AG

- BASI

- CALMET

- DV Power

- DANATRONICS

- Dioxide Materials

- ED & D

- ELVEFLOW

- ECH

- Elsys

- EA Technology

- Enapter

- Electrothermal

- Enervac

- EL-CELL

- ENERGY SUPPORT

- FASTEC

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GRZ

- HVPD

- HIGH SENSE SOLUTIONSHTW

- HUBER

- IVIUM

- Ida

- Instytut Fotonowy

- JGG

- Jacomex

- Jenway

- Kocos

- KEHUA TECH

- micrux

- Metrel

- Microrad

- METERTEST

- ndb

- Norecs

- Novocontrol

- Neware

- OKOndt Group

- OZM

- Pine Research

- Pinflow

- Redoxme

- SATIR

- Sonel

- Serstech

- SDT

- SENSIA

- SIKA

- SMC

- TANDELTA

- TENTECH

- Turnkey Instruments

- VacCoat

- Zurich Instruments

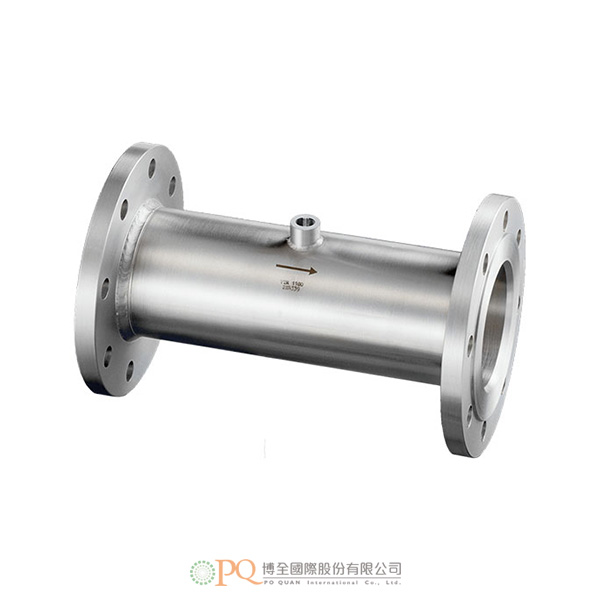

Turbine flow sensors with flange connection / Stainless steel version for indust

型號:Type VTR Flange- Robust stainless steel housing, also for difficult applications

- wide measuring ranges (1.8...45,090 l/min)

- high measuring accuracy, independent of installation position

- high-quality hard metal bearings with low wear and long service life

- variable use thanks to different measuring sensors as well as a variety of connection and nominal diameters

- SIKA works calibration certificate, 5-point calibration

-

The SIKA turbine flow sensors of the VTR series made of stainless steel are used in numerous areas due to their robust construction and high accuracy:

- industrial cooling circuits

- petrochemical / chemical industry

- water treatment / water conditioning

- plastics technology

- hydraulics

The VTR consists of the measuring turbine and the externally mounted measuring sensor. The measuring liquid flows into the measuring turbine and causes the rotor to rotate. The speed is directly proportional to the flow rate. The moving rotor blades are detected by the sensor and converted into a pulse signal which is proportional to the flow rate

- robust stainless steel housing, also for difficult applications

- wide measuring ranges

- high measuring accuracy, independent of installation position

- high-quality hard metal bearings with low wear and long service life

- variable use thanks to different measuring sensors as well as a variety of connection and nominal diameters

- SIKA works calibration certificate, 5-point calibration

Series

VTR

- Robust stainless steel body, even for difficult applications

- Wide measuring ranges (1.8…45090 l/min)

- High measuring accuracy, regardless of the mounting position

- High quality tungsten carbide bearings with low wear and long durability

- For variable use thanks to different pick-up sensors as well as a variety of connections and sizes

- Works calibration certificate 5 point calibration

-

Technical data

Accuracy

±0.5 % of reading*

Repeatability

±0.05 % of reading

Response time

< 50 ms up to DN 40

> 50 ms up to DN 300Process connections

Thread (up to DN 50): BSP ISO 228 Flange: DIN

Pressure drop

280 mbar at 100 % measurement range (density 1, viscosity 1 mm²/s)

Minimum pressure

2 x pressure drop of sensor

Pressure rating

Threaded connection: 250 bar

Flanged connection: corresponding to flange specificationMedium temperature

See technical data of the pick-up (page 4); max. 250 °C

All specified values apply to viscosities up to 5 cSt. Higher viscosities on request.

Options

For type

On request

VTR

Process connections

g ANSI

g NPT-Gewinde* Test conditions: Ex works, water 23 °C